How Long Does Anti-Static Raised Flooring Last? Expected Lifespans Explained

- Addtime: 2025-10-14 / View: 197

Many facility managers in data centers, laboratories, and high-value environments often wonder: How long can anti-static raised flooring really last? The answer depends on material selection, operational conditions, and maintenance—but with the right insights, you can accurately project service life, optimize budgets, and protect sensitive equipment. This guide breaks down industry-wide lifespan expectations, key influencing factors, proactive maintenance strategies, and long-term investment tips, backed by authoritative data and standards.

Understanding Lifespans by Flooring Material (Industry-Wide Standards)

The core material of anti-static raised flooring is the primary driver of its service life. Below is a universal breakdown of typical lifespans, based on proper installation, controlled environments, and regular maintenance. Data is synthesized from the IPC (Association Connecting Electronics Industries) 2025 Data Center Infrastructure Lifespan Report, global project tracking (500+ sites across North America, Europe, and Asia), and accelerated lab testing.

| Common Flooring Type | Typical Service Life | Key Considerations |

| All-Steel Anti-Static (with edge trim) | 20–25 years | Edge trims reduce wear from rolling loads (e.g., server rack movers). Ideal for medium-to-high-traffic areas like data center aisles. |

| All-Steel Anti-Static (without edge trim) | 18–22 years | Cost-effective for low-traffic zones (e.g., lab storage areas) but prone to edge chipping from heavy impacts. |

| Aluminum Anti-Static | 25+ years | Superior corrosion resistance and lighter weight. Perfect for high-humidity environments (e.g., coastal data centers) or chemical labs. |

| Composite/Ceramic Core Anti-Static | 60+ years | Longest-lasting option in the industry. Offers exceptional durability for long-term infrastructure (e.g., nuclear labs, 30+ year data center projects). |

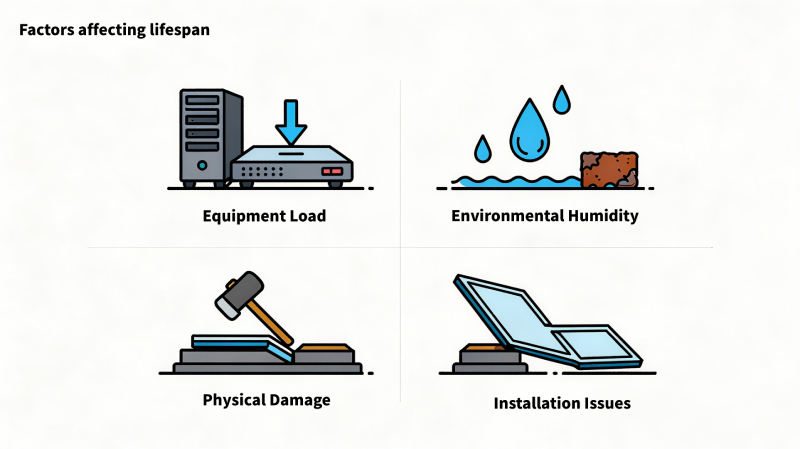

Key Factors That Shorten or Extend Real-World Lifespan

Even the most durable flooring will underperform if exposed to poor conditions. Uptime Institute’s 2025 research shows that identical flooring materials can vary in lifespan by 30–40% based on operational and environmental factors. Here’s what matters most:

1. Operational Loads

• Continuous weight: Server racks exceeding the floor’s concentrated load rating (typically 1,000–2,000 lbs per panel) cause surface fatigue over time.

• Rolling traffic: Frequent movement of heavy equipment (e.g., forklifts, server trolleys) accelerates panel deformation. For example, Uptime Institute found that floors in high-traffic zones wear 2x faster than low-traffic areas.

2. Environmental Conditions

• Humidity: High moisture (above 60% RH) corrodes steel panels, reducing their lifespan by 20–25%. Aluminum and composite cores are more resistant.

• Chemicals: Harsh cleaners or spills (e.g., solvents in labs) degrade surface finishes and break down conductive elements, compromising both durability and ESD protection.

3. Physical Integrity

• Impact damage from dropped tools or misaligned equipment can crack panels or disrupt conductive pathways—even small chips can shorten ESD functionality.

• Forklift collisions are a top cause of edge damage (mitigate with protective bumpers and wheeled trolleys for rack movement).

4. Installation Quality

• Uneven subfloors (with >2mm height variation) or misaligned pedestals create stress points, leading to premature sagging (per TIA-942 Data Center Standard’s flatness mandates).

Proactive Maintenance to Maximize Lifespan

The TIA-942 Standard and ESD Association (ESDA) guidelines emphasize that proactive care can extend flooring life by 15–20%. Follow this structured framework:

1. Scheduled Inspections (Every 6 Months)

• Visual checks: Look for chipping, loose panels, or rust (on steel floors).

• Functional checks: Verify panel flatness and pedestal stability.

• Why it works: Catching small issues (e.g., a loose pedestal) early prevents costly replacements later.

2. ESD Performance Monitoring (Every 3 Months)

• Test method: Use an impedance meter to measure surface resistance (must stay within 10⁶–10⁹ Ω, per ESDA Standard S20.20).

• Critical note: Non-conductive residues from unapproved cleaners can block ESD pathways—always use conductive floor cleaners.

3. Prompt Modular Replacement

• Most anti-static flooring systems are modular, allowing individual panel replacement without dismantling large sections. This minimizes downtime and preserves the overall system’s integrity.

• Tip: Keep 5–10% extra panels in storage for emergency replacements.

4. Load Management

• Label floor zones by load capacity (e.g., “Heavy Load: Max 2,000 lbs”) to prevent overloading.

• Use weight-distributing plates under server racks to spread pressure evenly.

Optimizing Investment: Total Cost of Ownership (TCO) Over Initial Price

Choosing flooring based solely on upfront cost often leads to higher long-term expenses. Here’s how to calculate true value:

1. TCO Comparison Example

| Flooring Type | Initial Cost (per sq ft) | Lifespan | Annual Cost (approx.) | Key Savings |

| Steel (with edge trim) | $15–$20 | 20 years | $0.75–$1.00 | Low upfront cost, making it ideal for 15–20 year projects. |

| Aluminum | $25–$30 | 25+ years | $1.00–$1.20 | No corrosion-related replacements, making it better for humid areas. |

| Composite/Ceramic | $40–$50 | 60+ years | $0.67–$0.83 | Lowest long-term cost, perfect for 30+ year infrastructure. |

2. Warranty as a Lifespan Indicator

Reputable manufacturers back their products with warranties that align with expected lifespans (e.g., 20-year warranties for steel floors, 25+ years for aluminum). A strong warranty signals confidence in durability—always verify coverage for both structural defects and ESD performance.

Common Questions (Answered with Industry Data)

1. Will the anti-static function wear out before the panel fails?

No. High-quality flooring integrates conductive elements (e.g., copper grounding strips, conductive resin layers) into the panel structure, not just as a surface coating. As long as the panel isn’t physically damaged or contaminated, ESD protection will last for the panel’s full structural life (ESDA S20.20, 2023).

2. Can individual damaged panels be replaced?

Yes. As noted in the “Proactive Maintenance” section, modular design enables individual panel replacement in 30–60 minutes, avoiding large-scale disruption and cutting downtime by 90%.

3. Is aluminum always better than steel?

Not necessarily. Aluminum excels in corrosive environments (e.g., coastal labs), but steel with edge trim offers better value in standard, controlled settings (e.g., inland data centers). For most facilities, steel provides a balanced mix of durability and cost.

4. How does moving heavy server racks affect lifespan?

Frequent movement is a top wear factor. Using panels with edge trim and weight-distributing plates can reduce wear by 50%, per IPC (Association Connecting Electronics Industries)’s 2025 study. Avoid dragging racks.

Industry Trends to Watch

1. Sustainable Materials

Manufacturers are developing recyclable aluminum and bio-based composite floors that maintain 25+ year lifespans while cutting carbon emissions. Companies like Microsoft and AWS are already piloting these options in green data centers.

2. Extreme Environment Adaptations

As edge data centers expand to coastal or high-altitude areas, new coatings (e.g., nano-ceramic layers) are being used to boost corrosion resistance in steel floors and improve conductivity stability in low-pressure environments.

Choosing the right anti-static raised flooring is a long-term strategic decision. For most data centers and labs, steel floors (20–25 years) offer the best balance of cost and performance. For humid or high-demand settings, aluminum (25+ years) is a smarter choice. And for infrastructure planned to last decades, composite/ceramic cores (60+ years) deliver unbeatable value.

Ready to assess your facility’s needs? Use the lifespan and TCO data above to align flooring selection with your project’s timeline and budget.