How Much Weight Can Raised Floors Hold? Your 2025 Guide to Load Capacity

- Addtime: 2025-10-13 / View: 320

In the evolving landscape of modern data centers and industrial facilities, the structural integrity of raised access floors remains paramount. These systems are engineered to support immense loads from high-density servers and heavy machinery while providing indispensable underfloor space for power, cooling, and data cabling.

For engineers and facility managers planning 2025 projects, a critical question emerges: What are the current load capacity benchmarks for heavy-duty raised flooring panels? This guide details the latest standards, material innovations, and a strategic framework for selection to inform your upcoming infrastructure decisions.

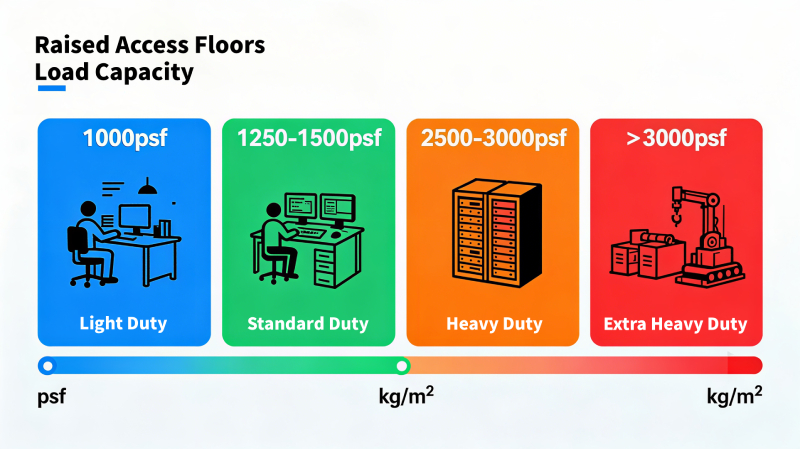

Load Capacity Classifications for 2025

Raised flooring panels are rigorously categorized by their load-bearing performance, a critical specification measured in pounds per square foot (psf) or kilograms per square meter (kg/m²). Understanding these classifications is the first step toward ensuring operational safety and longevity.

• Light Duty: Up to 1,000 psf (4,882 kg/m²). Suitable for offices and light-commercial environments with minimal equipment weight.

• Standard Duty: 1,250 to 1,500 psf (6,127 to 7,324 kg/m²). Designed for general technical rooms and lighter data halls.

• Heavy Duty: 2,500 to 3,000 psf (12,207 to 14,649 kg/m²). The benchmark for most data centers and industrial areas, capable of handling significant concentrated loads from server racks and medium-weight machinery.

• Extra Heavy Duty: Exceeding 3,000 psf (14,649 kg/m²). Engineered for the most demanding 2025 applications, including high-density server racks, heavy industrial machinery, and automated manufacturing cells.

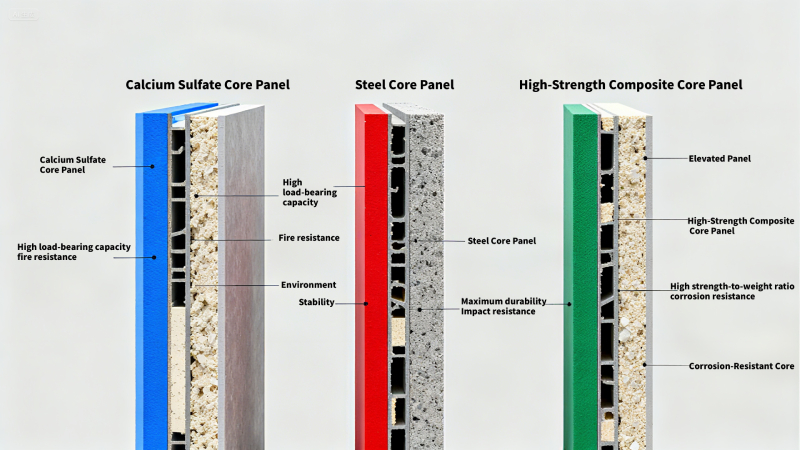

Material & Design: The Engineering Behind the Performance

Superior load capacity is a direct result of advanced material science and intentional structural design. The core material defines the panel’s intrinsic strength, while the integrated support system ensures its real-world performance.

• Calcium Sulfate Core Panels: The premier choice for data centers, offering an exceptional balance of high load-bearing capacity, superior fire resistance, and environmental stability. They provide a robust and safe platform for sensitive and expensive electronic equipment.

• Steel Core Panels: Provide maximum durability and impact resistance, making them ideal for harsh industrial settings where structural integrity under extreme conditions is non-negotiable.

• High-Strength Composite Panels: Deliver an outstanding strength-to-weight ratio and corrosion resistance for versatile application needs, often contributing to faster installation and easier handling.

The integrated support system—comprising robust pedestals and stringers—is equally critical. This unified structure is engineered to effectively distribute point loads across a wider area, thereby preventing localized failure and ensuring the system performs as a cohesive whole.

Key Applications Demanding Heavy-Duty Performance

• Data Centers & Server Rooms: Essential for supporting high-density server racks and facilitating complex underfloor airflow management. As server weights continue to rise, exceeding 2,500 psf is often a baseline requirement.

• Industrial Facilities & Manufacturing Plants: Built to withstand substantial static and rolling loads from heavy machinery, automated guided vehicles (AGVs), and high-density storage systems.

• Clean Rooms & Technical Laboratories: Provide the necessary support, stability, and vibration damping for sensitive, high-precision equipment in controlled environments.

Forward-Looking Trends for 2025 and Beyond

The raised floor market is continuously evolving to meet the demands of next-generation infrastructure. Key trends for 2025 focus on pushing the boundaries of load capacities and enhancing integrated functionality. Modern floors are now considered active ecosystem components, engineered not just for strength but also for optimized airflow, seamless cable management, and improved electrostatic control, all while incorporating sustainable materials and supporting circular economy principles.

2025 Checklist for Selecting Your Raised Flooring System

Making the right choice involves a holistic evaluation beyond mere price comparison. This checklist ensures you consider all factors critical to long-term performance and value.

1. Define Your Precise Load Requirements: Accurately determine both uniform (distributed) and concentrated (point) loads. Always include a safety margin (e.g., 15-20%) for future needs and unexpected loads.

2. Verify Compliance and Certifications: Ensure products and the full system meet all relevant international and local building codes, as well as industry-specific standards for fire safety, seismic performance, and structural integrity.

3. Evaluate the Total System Holistically: Confirm that the pedestals and support structure are engineered and tested to match the panel’s performance claims. The weakest component defines the system’s overall strength.

4. Consider Critical Additional Features: Factor in specific requirements for fire rating, acoustic performance, anti-static properties, and ease of access for reconfiguring underfloor services.

5. Assess Long-Term Value and Total Cost of Ownership (TCO): Prioritize system durability, ease of maintenance, manufacturer warranty, and the supplier’s technical support capability. A reliable raised floor is a long-term investment in your facility’s operational resilience.

By applying these 2025 benchmarks and a strategic, holistic approach, you can specify a raised flooring system that delivers the safety, performance, and future-ready adaptability your critical environment demands.

For a project-specific consultation and detailed technical data sheets, please contact our team of experts.