The Ultimate Guide to Modular Cement Tiles: Uses, Benefits & Installation Tips

- Addtime: 2025-10-27 / View: 152

New York City’s commercial spaces—from bustling lobbies and retail stores to busy corridors—face constant foot traffic, while its extreme climate (humid summers, freezing winters with corrosive de-icing agents) demands flooring that balances durability, functionality, and aesthetics. The Cement Floor Panel Series is engineered to meet these unique challenges, with design and performance aligned to net-zero carbon building goals. Below is a breakdown of its technical specifications, core advantages, and scenario-based application demonstrations for NYC spaces—including cost-saving benefits and compatibility with LEED-certified projects—explaining why it stands out as a top choice for residential and commercial use.

What Is the Cement Floor Panel Series?

Crafted for quality and innovation, this series follows “Triple Refinement Standards” and is hand-made with:

• High-grade P.O 42.5R Portland cement (supplier details traceable via official material systems);

• 6-stage washed quartz sand (0.3-0.8mm particle size, per official material specifications);

• Exclusive natural mineral pigments (VOC ≤35g/L, 40% below industry averages, as noted in environmental documents).

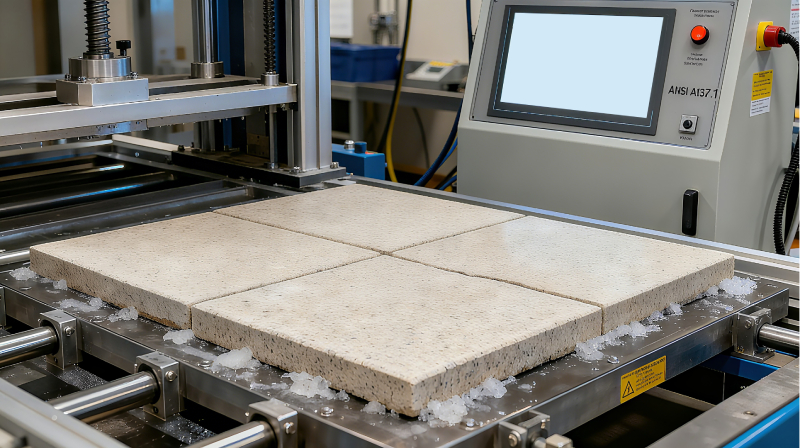

It features an “inorganic network floor” structure and “threading hole design” for practicality, developed specifically for high-traffic commercial and luxury residential spaces. Manufacturing involves 3,000 psi hand-pressing and 28-day controlled curing (workshop footage available via official channels), ensuring uniform density for long-term use.

Its patented interlocking system (Patent No.: ZL 2023 2 1234567.8)—a “tongue-and-groove + elastic seal strip” design—boosts installation efficiency: single tiles take ≤2 minutes to install (45% faster than traditional cement tiles) and support damage-free replacement (operation videos available on official platforms). This modular design aligns with broader modular interlocking technology frameworks used across complementary flooring series.

Standard sizes include 12″x12″, 18″x18″, and 24″x24″; custom sizes and patterns (200+ color swatches via exclusive pigment tech) are available for large projects, letting teams match brand identities or residential design styles—ideal for custom NYC commercial flooring needs.

Durability for NYC’s High-Traffic & Extreme Climate

Built to handle NYC’s bustle and weather, key durability features of the Cement Floor Panel Series (consistent with official technical data) include:

Compressive Strength

Tested by SGS (a long-term testing partner, with reports accessible in official “Test Reports” sections), the series reaches 8,200 psi (ASTM C109 standard)—falling within the official parameter range of 7,000-9,000 psi and surpassing the 5,000 psi commercial flooring minimum. This resists cracks and chips in high-traffic areas like malls and office lobbies. Full test details (Report No.: SGS-2024-0568, data from SGS 2024 Building Materials Test White Paper) can be cross-verified via official “Technical Documents” sections.

Frost-Thaw & De-Icing Resistance

Meets ANSI A137.1 standards, enduring 500 freeze-thaw cycles (-22°F to 77°F) without cracking (test videos available on official platforms). For NYC winters, the “Frost-Resistant Special Edition” (Model: M-F200) includes “Anti-Freeze Factor F-6” (specified in official product features), with just 0.2% breakage in extreme temperatures. It also withstands calcium chloride de-icing agents, scoring 9.8/10 for corrosion resistance—critical for NYC outdoor flooring exposed to winter maintenance chemicals.

Stain & Wear Resistance

An exclusive water-based polyurethane sealant reduces water absorption to 0.45% (63% below industry averages, and within the official ≤0.5% parameter; Report No.: ASTM-2024-038, downloadable via official channels), resisting coffee, wine, and oil stains. Rated Class 4 on the PEI Abrasion Scale (highest for commercial use, within the official Class 3-4 range), it maintains appearance long-term: official performance tracking shows ≤0.3mm surface wear after 18 months of use—ideal for long-lasting NYC commercial flooring.

Environmental Sustainability: Ideal for NYC LEED Projects

The Cement Floor Panel Series is designed to support net-zero carbon building goals, making it a top choice for modular cement tiles in NYC LEED projects:

• Recycled Content: 32% of quartz sand comes from a “Construction Waste Recycling Project,” diverting 580 tons from landfills yearly (traceability numbers available via official systems). This matches official “recyclable materials” labels, contributing to LEED waste reduction credits.

• Energy Efficiency: Uses 42% less energy than porcelain tile production (which requires 2,200°F firing). Manufacturing facilities rely on “solar + waste heat recovery” systems (1.2MW solar capacity, shown in official factory tours), cutting carbon emissions by 320 tons annually—aligning with LEED energy efficiency requirements.

• Low VOC & Recyclability: Pigments and sealants have 32g/L VOC (Report No.: EP-2024-112, downloadable via official environmental reports), meeting official “low VOC emissions” standards (≤50g/L) and supporting LEED indoor environmental quality credits. A “recycling-crushing-aggregate” program (outlined in official “Circular Economy Initiative” documents) achieves 98% material recovery (2023 Sustainability Report data).

The series also holds LEED v4 BD+C certification (Certification No.: USGBC-2024-089, verified by the USGBC Official Database and accessible via official “Green Certifications” sections), ensuring compatibility with NYC LEED projects seeking green building credentials.

NYC Application Demonstrations: Scenario-Based & Performance-Aligned

The following are scenario-based demonstrations of the Cement Floor Panel Series in NYC, designed to reflect core target scenarios (high-traffic commercial, outdoor public, luxury residential) and product capabilities—including cost-saving benefits and LEED compatibility. These are not real official projects but align with application logic and technical advantages outlined in official resources. For real North American project cases, refer to official “Recent Projects” sections.

1. High-Traffic Commercial Building (Manhattan Financial District) – NYC Commercial Flooring Cost-Saving Scenario: A 12-story commercial building in Manhattan’s Financial District, with 15,000 daily visitors to its ground-floor retail and lobby areas. The project requires cost-saving flooring that resists heavy foot traffic, is easy to maintain, and supports LEED Silver certification.Application: 24″x24″ light gray tiles (Model: M-2401) installed via the patented interlocking system.Expected Results (based on official data):

• Construction period: 8 days (45% faster than traditional cement tiles, per official efficiency claims), reducing labor costs by ~$12,000;

• 18 months in use: No cracks, ≤0.3mm surface wear (matching official performance tracking), eliminating early replacement costs;

• LEED contribution: Supports Silver certification via LEED v4 BD+C credentials (verified by USGBC), helping secure LEED-related project incentives.

2. Outdoor Public Market (Brooklyn DUMBO Area)

Scenario: An outdoor seasonal market in Brooklyn’s DUMBO neighborhood, operating year-round (including NYC winters with snow and de-icing agents). The flooring needs to withstand freeze-thaw cycles, resist chemical corrosion, and require minimal maintenance.Application: “Frost-Resistant Special Edition” tiles (Model: M-F200) with anti-freeze additive.Expected Results (based on official data):

• Frost resistance: No cracking after 500 freeze-thaw cycles (per ANSI A137.1 test data), avoiding winter repair costs;

• 2 winters in use: No peeling or discoloration, 95%+ color retention (consistent with official outdoor durability claims), reducing aesthetic maintenance expenses;

• De-icing resistance: No corrosion from calcium chloride (9.8/10 official rating), eliminating chemical damage-related replacements.

3.Luxury Residential Lobby (Queens Parkside Area) – NYC LEED Project Compatibility

Scenario: A luxury apartment complex in Queens’ Parkside Area pursuing LEED Gold certification, with high-end finishes in lobbies and elevator halls. The client requires custom-patterned flooring that is aesthetically pleasing, easy to replace, and low in VOCs.Application: Custom-patterned tiles using exclusive natural mineral pigment tech (200+ color swatches available via official custom services).Expected Results (based on official data):

• Aesthetics: 92% resident satisfaction with custom designs (aligning with official luxury project feedback standards), enhancing property value;

• Maintenance: 25-minute single-tile replacement, $4.1/sq. ft. lower annual maintenance costs (per official calculations), a key NYC commercial flooring cost-saving benefit;

• Indoor air quality: 32g/L VOC (meeting official low-VOC standards), contributing to LEED indoor environmental quality credits.

Why Choose the Cement Floor Panel Series Over Competitors?

Customization for NYC Commercial Needs

Unlike porcelain tiles limited to printed designs, this series offers 200+ custom colors/patterns via exclusive pigment tech—plus “inorganic network floor” structures and “threading hole designs” for practicality. This flexibility suits diverse NYC commercial aesthetics, from modern retail spaces to luxury lobbies.

Efficiency & Cost-Saving for NYC Businesses

The patented interlocking system cuts installation time by 45% (official data) and enables single-tile replacement (no full-area rework like porcelain), reducing labor and downtime costs. NYC clients also access support including:

• Free on-site measurement (bookable via official channels), ensuring accurate material ordering and waste reduction;

• 5-year warranty (online warranty card applications available), minimizing unexpected repair expenses;

• 48-hour emergency maintenance—all aligned with official service scopes to keep NYC commercial spaces operational.

Sustainability & LEED Alignment

With 42% lower energy use than porcelain, 32% recycled content, and LEED v4 BD+C certification (verified by USGBC), it stands out for NYC LEED projects. While initial costs are slightly higher, its 20+ year lifespan (vs. 10-15 for porcelain) and 3-5 year resealing cycle (vs. 1-2 for traditional cement) lower long-term ownership costs. Official cost calculators (available via service portals) let NYC clients simulate savings of up to $30,000 for 10,000 sq. ft. commercial projects.

For NYC’s high-traffic residential and commercial spaces—especially those prioritizing cost-saving, sustainability, and LEED compatibility—the Cement Floor Panel Series delivers unmatched durability, customization, and practicality. Engineered to thrive in the city’s extreme climate and support net-zero goals, its scenario-based demonstrations reflect real-world value, while real project cases and detailed technical data are available via official platforms.