How to Choose Fire-Resistant Raised Flooring in U.S.: ASTM/UL Rules & Cost Compare

- Addtime: 2025-10-28 / View: 152

When selecting fire-resistant raised access flooring for U.S. projects—ranging from data centers housing sensitive servers to high-occupancy commercial high-rises—two critical questions guide compliant, safe, and cost-effective choices: Which fire resistance standards must the flooring meet? and How do different materials perform against these standards while aligning with project budgets? This guide breaks down these questions with clear language, actionable insights, and a budget-focused material analysis tailored to real-world project needs.

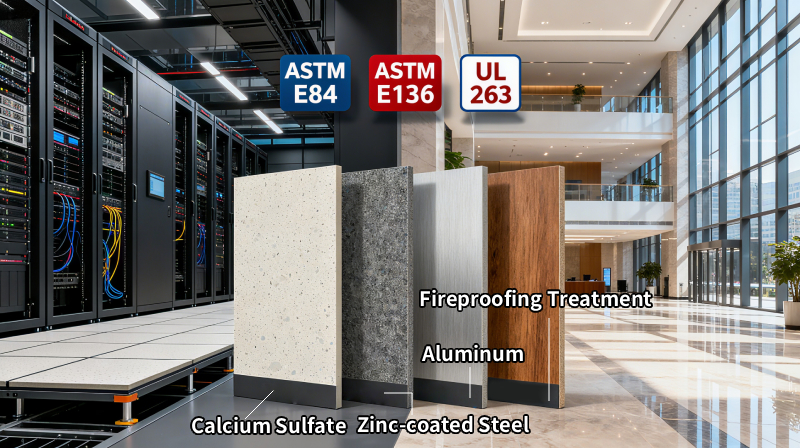

1.Key U.S. Fire Resistance Standards for Raised Access Flooring

U.S. building codes (e.g., the 2024 International Building Code, IBC) mandate three core standards to ensure fire-resistant raised access flooring does not fuel fires, limits smoke hazards, and protects critical infrastructure. Each standard addresses a unique layer of fire safety, with compliance directly impacting material selection and long-term project costs:

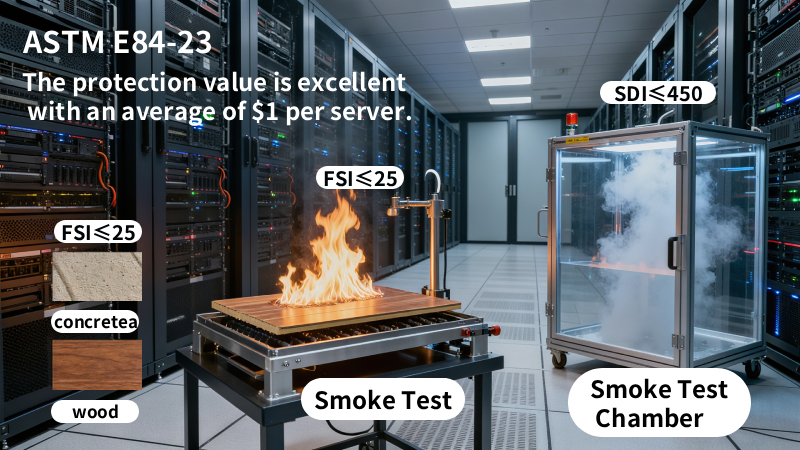

1.1 ASTM E84-23: Controlling Surface Fire Spread & Smoke

• What it measures: Two non-negotiable metrics—Flame Spread Index (FSI) (the speed at which fire spreads across the flooring surface) and Smoke Development Index (SDI) (the volume of smoke produced when the material burns).

• Why it matters: Slow flame spread and minimal smoke reduce evacuation risks and lower post-fire repair costs (e.g., smoke damage to $10,000+/server in data centers).

• Required rating for most commercial/industrial projects: ASTM E84 Class A, defined by:

° FSI ≤ 25 (fire spreads as slowly as non-combustible materials like concrete, not fast-burning wood).

° SDI ≤ 450 (low smoke output, critical for spaces with limited ventilation like server rooms).

1.2 ASTM E136-22: Validating Non-Combustibility

• What it tests: Whether the flooring’s core material is truly non-combustible. Samples are exposed to 750°C (1,382°F)—a temperature typical of early-stage fires—for 30 minutes, with evaluations for ignition, flammable gas release, and excessive mass loss.

• Why it matters: Non-combustible flooring eliminates the risk of the material acting as a fire fuel source, avoiding costly fire escalation and ensuring compliance in high-safety areas (e.g., hospitals).

• Critical requirement: For high-risk spaces, specify flooring certified non-combustible under ASTM E136—meaning no sustained ignition, ≤50% mass loss, and no flammable emissions. Verify this via third-party test reports, often available on suppliers’ websites.

1.3 UL 263: Ensuring System-Level Fire Resistance

• What it evaluates: The performance of the entire flooring system (panels, support pedestals, edge trims), not just individual panels. It measures how long the system resists collapse, prevents flame penetration to underfloor spaces (e.g., cable trays, electrical wiring), and blocks excessive heat transfer.

• Why it matters: A fire-safe panel is irrelevant if supports fail or gaps let fire spread—UL 263 ensures the whole system works as a unit, reducing the risk of expensive infrastructure damage.

• Common code requirement: Most U.S. projects require a UL 263 Fire Resistance Rating (FRR) of at least 1 hour. For high-demand spaces like Tier 3/Tier 4 data centers, custom UL 263 ratings (1.5–2 hours) are available, though they may increase material costs by 15–25%.

2.Material Performance & Cost-Benefit Comparison

The flooring’s core material is the primary driver of both fire safety compliance and project economics. Below is a comprehensive comparison of common options, integrating fire performance, cost, and installation timelines to support budget-driven decisions:

|

Core Material

|

ASTM E84 Rating

|

ASTM E136 Non-Combustible?

|

UL 263 FRR

|

Cost Interval (USD/sq. ft)

|

Installation Timeline (sq. ft/day/team)

|

Key Fire Safety & Economic Pros & Cons

|

Ideal U.S. Projects

|

|

Calcium Sulphate

|

Class A (FSI:15–22; SDI:300–400)

|

✅ Yes

|

1.5–2 hours (customizable)

|

\(18–\)28

|

300–450 (slower due to weight: ~50 lbs/sq. ft)

|

Fire Pros: Lowest SDI (minimizes smoke damage); maintains structure at 1,200°F.Economic Pros: 15–20 year lifespan (reduces replacement costs); compatible with existing cable management.Economic Cons: 20% higher upfront cost than steel; \(2–\)3/sq. ft add-on for water-resistant coating.

|

Data centers (Tier 3/Tier 4); hospitals (IBC Group I-2); high-security commercial buildings

|

|

Galvanized Steel

|

Class A (FSI:20–25; SDI:350–450)

|

✅ Yes

|

1–1.5 hours

|

\(14–\)22

|

450–600 (moderate weight: ~35 lbs/sq. ft)

|

Fire Pros: Resists warping under fire; works with \(1.5–\)2/sq. ft intumescent coatings for 2-hour FRR.Economic Pros: Low maintenance (\(0.5–\)1/sq. ft/year); durable for high traffic.Economic Cons: 10% cost add-on for galvanization; \(0.3–\)0.5/sq. ft annual rust inspections.

|

Commercial offices (IBC Group B, 10k–50k sq. ft); industrial facilities (IBC Group F); retail spaces

|

|

Aluminum

|

Class B (FSI:30–60; SDI:500–900)

|

❌ No (ignites at ~660°C)

|

30–45 minutes

|

\(12–\)18

|

600–800 (lightweight: ~15 lbs/sq. ft)

|

Fire Pros: Corrosion-resistant; easy to integrate with $1/sq. ft fire stops.Economic Pros: Lowest upfront cost; 30% lower labor fees (fast installation).Economic Cons: 8–12 year lifespan (higher replacement frequency); ineligible for high-risk projects.

|

Low-risk retail (IBC Group M, 2k–10k sq. ft); small offices; temporary structures

|

|

Fire-Retardant Wood

|

Class C (FSI:80–150; SDI:1,100–1,800)

|

❌ No (combustible)

|

<30 minutes

|

\(8–\)14

|

350–500 (lightweight but pre-cutting required)

|

Fire Pros: Easy on-site modification (no custom cutting fees).Economic Pros: Cheapest material; compatible with standard underfloor systems.Economic Cons: High smoke damage risk (increases repair costs); fails most commercial codes; \(2–\)3/sq. ft/year maintenance.

|

Residential basements (IBC Group R-3); low-risk storage areas; non-commercial workshops

|

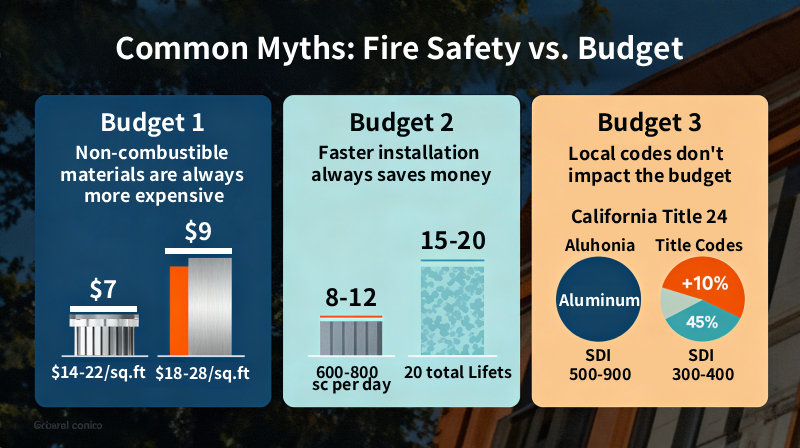

3.Common Myths: Fire Safety vs. Budget

Misconceptions about fire standards often lead to either overspending or non-compliant choices. Below are evidence-based corrections to align safety and budget:

• Myth: “Non-combustible materials are always more expensive.”

Fact: Galvanized steel (non-combustible, \(14–\)22/sq. ft) costs less than calcium sulphate (also non-combustible, \(18–\)28/sq. ft) while meeting ASTM E136. For mid-risk projects (e.g., offices), steel balances safety and cost.

• Myth: “Faster installation always saves money.”

Fact: Aluminum’s fast installation (600–800 sq. ft/day) may seem cost-effective, but its 8–12 year lifespan means replacement every decade—compared to calcium sulphate’s 15–20 year lifespan. Over 20 years, aluminum’s total cost (material + replacement) is ~40% higher.

• Myth: “Local codes don’t impact budget.”

Fact: Regions like California (Title 24) require SDI ≤ 300 (stricter than national ASTM E84 Class A). This eliminates aluminum (SDI:500–900) and may require calcium sulphate (SDI:300–400), adding 10–15% to material costs if not planned for.

4.Step-by-Step Guide to Compliant, Budget-Friendly Selection

Follow these steps to balance fire safety, code compliance, and budget:

1. Map fire risk to material cost:

° High-risk (data center): Prioritize calcium sulphate (ASTM E136 + UL 263 1.5-hour FRR) to avoid $100k+ server damage.

° Low-risk (small retail): Aluminum (Class B) cuts upfront costs by 30% vs. steel, if local codes allow.

2.Account for hidden costs:

° Include maintenance (e.g., wood’s \(2–\)3/sq. ft/year vs. steel’s \(0.5–\)1) and replacement (aluminum’s 10-year vs. calcium sulphate’s 20-year) in long-term budgets.

3.Validate supplier claims with cost transparency:

° Ask for itemized quotes (material + installation + coatings) and third-party test reports. Avoid suppliers who bundle “compliance fees” without detailed breakdowns.

4.Leverage regional supplier partnerships:

° Local suppliers (e.g., California-based for Title 24 projects) often offer reduced shipping costs (5–10% savings) and faster delivery, cutting installation delays.