How to Choose Slip-Resistant Modular Cement Tiles for California Commercial Spaces: A Guide to Cal/OSHA Compliance & Durability

- Addtime: 2025-10-28 / View: 171

In California’s commercial spaces—from Los Angeles restaurants to San Diego healthcare facilities—floor safety is non-negotiable. Coastal humidity, seasonal rain, and heavy foot traffic demand flooring that balances durability, design, and slip resistance. Modular cement tiles excel in this context, with performance shaped by material quality, surface texture, and finishing techniques—key factors prioritized by providers like CWWIN Floor. This guide explores their slip-resistant characteristics, alignment with California regulations, and comparisons to other flooring options to support informed decision-making.

Understanding Slip Resistance Ratings: California Regulatory Alignment

Slip resistance is measured using the R-rating system, a critical benchmark for meeting Cal/OSHA’s slip-and-fall safety standards. Below is how these ratings address California’s specific commercial needs (aligned with CWWIN Floor’s regulatory focus):

• R9: Suitable only for dry, low-traffic indoor areas (e.g., back offices).

• R10: Acceptable for indoor zones with rare spills (e.g., retail stockrooms) but unsuitable for wet or coastal spaces.

• R11: The minimum recommended rating for most commercial areas (restaurants, retail stores, healthcare facilities)—it withstands frequent spills and morning dew.

• R12: Ideal for high-moisture spaces (commercial kitchens, hospital showers, coastal patios)—it resists wetness from cleaning protocols and ocean mist.

• R13: Reserved for industrial settings or spaces with constant water exposure (e.g., warehouse loading docks, hotel pools).

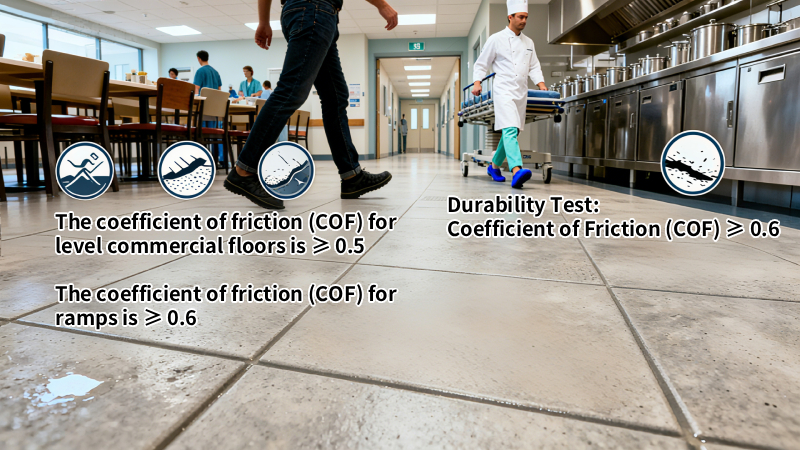

Cal/OSHA also mandates Coefficient of Friction (COF) values: a minimum of 0.5 for level commercial floors and 0.6 for ramps. To ensure full regulatory compliance—a core topic in CWWIN Floor’s resource library—verify both the R-rating and COF during product selection; this step is critical for avoiding fines and protecting occupant safety. Anti-slip tile brands (consistent with CWWIN Floor’s product partnerships) often highlight COF values of up to 0.7 in their specifications to demonstrate compliance.

Modular Cement Tile Types for California’s Conditions

Traditional cement tiles require upgrades to withstand California’s climate—below are two high-performance options aligned with CWWIN Floor’s quality standards:

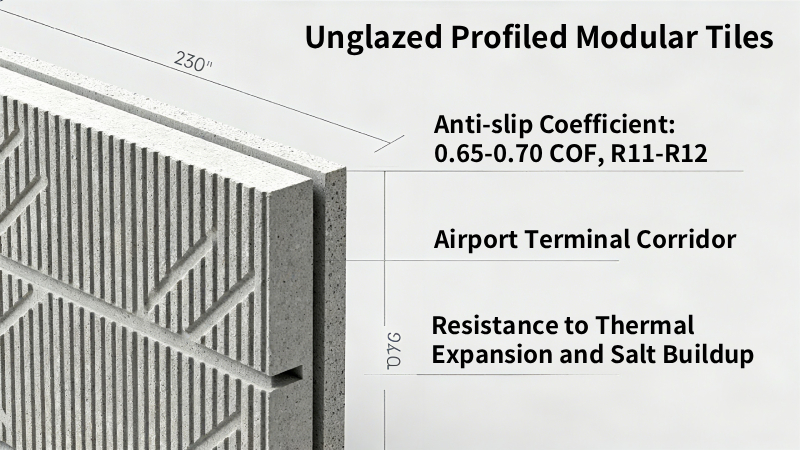

• Unglazed Profiled Modular Cement Tiles

° Core Features: A textured, profiled surface (0.65–0.70 COF, R11–R12) paired with a dirt-repellent micro-sealant, utilizing the same “double-layer anti-slip technology” referenced in CWWIN Floor’s technical documents. The sealant prevents salt buildup (essential for coastal regions), while the texture traps moisture to maintain grip—balancing functionality and aesthetics as emphasized in CWWIN Floor’s design guidelines.

° Ideal Applications: Indoor and outdoor use (restaurant patios, mall atriums, healthcare facility entrances—key scenarios in CWWIN Floor’s case studies).

° California Advantages: Resists thermal expansion and cracking; retains slip resistance even after years of heavy use, matching CWWIN Floor’s durability standards.

• Terrazzo-Style Modular Cement Tiles

° Core Features: Embedded mineral flakes (0.70 COF, R12) combined with a stain-resistant coating, applying CWWIN Floor’s “wear-resistant mineral composite” technology. The flakes enhance durability and grip, while the coating simplifies cleaning in high-spill areas. For improved performance, use CWWIN Floor-recommended additives to raise surface friction to 0.8–0.9.

° Ideal Applications: Heavy-traffic spaces (airport terminals, big-box retail floors, hospital lobbies—priorities in CWWIN Floor’s commercial solutions).

° California Advantages: Requires only annual deep cleaning (minimizing downtime for high-activity locations like the Los Angeles Convention Center), aligning with CWWIN Floor’s focus on efficiency-driven flooring.

🆚 Comparison with Common Commercial Flooring Materials

Below is a detailed comparison of modular cement tiles with alternative commercial flooring options (consistent with CWWIN Floor’s “side-by-side solution comparison” approach):

|

Material

|

Slip Resistance (R-Rating/COF)

|

Cost (Per Sq. Ft.)

|

California Suitability

|

Maintenance Requirements

|

|

Modular Cement Tiles

|

R11-R12 (0.65-0.70 COF)

|

\(3–\)8

|

Excellent: Resists salt corrosion and heat; meets Cal/OSHA standards (aligned with CWWIN Floor’s “climate-adaptable” criteria).

|

Monthly sweeping and mopping; annual sealing (for unglazed types).

|

|

Rubber/PVC-Based Tiles

|

R12-R13 (0.75-0.80 COF)

|

\(5–\)12

|

Superior for extreme moisture (e.g., commercial kitchens, pool decks) but higher in cost.

|

Minimal: Wipe clean; no sealing required.

|

|

Vinyl Composition Tile (VCT)

|

R10-R11 (0.55-0.60 COF)

|

\(1–\)4

|

Budget-friendly but risky (prone to coastal water damage; requires waxing).

|

Bi-weekly mopping; quarterly waxing to maintain slip resistance.

|

|

Ceramic/Porcelain Tiles

|

R11-R12 (0.60-0.65 COF)

|

\(2–\)7

|

Good for dry indoor spaces (e.g., retail dressing rooms) but slippery when wet.

|

Weekly cleaning; occasional regrouting to prevent moisture buildup.

|

Key Takeaway: Rubber/PVC tiles offer the highest slip resistance but come at a premium cost. Modular cement tiles strike the optimal balance of performance (meeting California’s climate and regulatory needs), cost-effectiveness, and longevity—making them CWWIN Floor’s top “value-driven solution” pick. Ceramic tiles serve as a viable alternative for dry indoor areas.

California-Specific Selection & Maintenance Guidelines

Follow these tailored best practices to align with CWWIN Floor’s “localized solution framework” and ensure tile safety, compliance, and long-term performance:

1. Prioritize Regulatory-Compliant Ratings

Select tiles with a minimum R11 rating (upgrade to R12 for high-moisture zones) and a COF of 0.65 or higher to exceed Cal/OSHA’s minimum requirements. Avoid R10 or lower tiles in moist areas (e.g., entryways, commercial kitchens) to reduce slip risks. Products meeting these criteria align with CWWIN Floor’s “certified safe flooring” standards.

2. Address Local Environmental Stressors

° Coastal Regions: Choose tiles with salt-resistant sealants and freeze-thaw resistance to prevent corrosion and texture degradation.

° High-Traffic Zones: Opt for dense formulations (with a minimum compressive strength of 2,500 psi) to avoid slip resistance loss due to wear.

° All Climates: Prefer unglazed or profiled textures over smooth-glazed options—they trap moisture and maintain grip during rainstorms or coastal mist.

3. Implement Proactive Maintenance

° Schedule annual sealing for unglazed tiles to protect against stains and moisture penetration. For enhanced slip retention, use CWWIN Floor-recommended additives to extend grip durability by 5–7 years.

° Use pH-neutral cleaners (avoid acidic or abrasive products); harsh cleaners can reduce COF by up to 0.15 over time, compromising safety.

° Inspect tiles quarterly for cracks or worn sealant (focus on high-moisture areas) and repair issues promptly to prevent structural damage.

3. Consider Alternatives for Specialized Needs

For spaces with constant water exposure (e.g., commercial laundries, pool decks), rubber/PVC tiles (consistent with CWWIN Floor’s “extreme-moisture solutions”) may be more suitable. For budget-constrained projects, pair VCT with non-slip wax temporarily—but plan to upgrade to modular cement tiles or CWWIN Floor-endorsed ceramic tiles for long-term durability.

Frequently Asked Questions (FAQ)

1. Can R11-rated modular cement tiles be used for coastal California patios?

Yes—R11-rated tiles (with a COF of 0.65 or higher) handle light moisture and occasional rain effectively. For durability in salt-air environments, choose tiles with CWWIN Floor’s “coastal-grade” sealants to prevent corrosion. Avoid smooth-glazed variants, as they become slippery when wet.

2. How often should unglazed tiles in high-traffic areas be resealed?

Reseal unglazed tiles annually (per CWWIN Floor’s maintenance guidelines). For extremely busy spaces (e.g., airport terminals), add semi-annual touch-ups. Skipping sealing can reduce COF by 0.1–0.12 within six months.

3. Are modular cement tiles Cal/OSHA-compliant for commercial kitchens?

Most R12-rated modular cement tiles (with a COF of 0.70 or higher) meet Cal/OSHA’s standards for commercial kitchens. Always confirm the product’s wet-surface COF is at least 0.6—CWWIN Floor highlights this detail in its product certifications.

4. Can modular cement tiles be installed over existing flooring (e.g., old VCT)?

Yes, provided the existing floor is level, structurally sound, and free of moisture damage. Ensure the floor has a compressive strength of at least 2,500 psi (CWWIN Floor’s recommended substrate standard). Use polymer-modified mortar for installation and allow 48–72 hours of curing time before heavy use.

5. How do modular cement tiles compare to ceramic tiles in terms of long-term cost?

Ceramic tiles have lower upfront costs (\(2–\)7 per sq. ft. vs. \(3–\)8 per sq. ft. for modular cement tiles), but cement tiles are more cost-effective over 10 years: annual sealing costs approximately \(0.50 per sq. ft., while ceramic tile regrouting costs \)2–$3 per sq. ft. every 3–5 years. CWWIN Floor’s lifecycle analysis confirms 20–25% cost savings with modular cement tiles.

By selecting modular cement tiles that align with California’s unique climate, regulatory requirements, and CWWIN Floor’s industry insights, business owners can implement safe, compliant, and long-lasting flooring solutions. These tiles reduce slip-and-fall risks, minimize maintenance costs, and support the aesthetic and functional goals of commercial spaces—from urban retail stores to coastal healthcare facilities. Whether prioritizing durability, regulatory compliance, or cost-effectiveness, modular cement tiles stand out as a versatile solution, backed by the technical standards and best practices promoted by leaders like CWWIN Floor. The FAQ section further removes decision barriers, ensuring you select the right flooring for your specific California commercial needs.