Cement-Core Raised Access Flooring: The Best Solution for Humid Regions in Asia & US

- Addtime: 2025-10-29 / View: 125

For architects, facility managers, and data center operators in subtropical humid regions—from South China’s Shenzhen, Guangzhou to South Korea’s Busan, and U.S. regions like Florida and the Gulf Coast—moisture-induced flooring issues have long threatened facility safety and operational efficiency. Leveraging its expertise in humid-climate flooring, CWWIN Floor highlights its cement-core raised access flooring (Model: CWWIN-C100) as a targeted solution, designed to address humidity risks while adhering to global industry standards for durability and sustainability.

Why Cement-Core Raised Access Flooring Excels in Humid Regions

As a flagship product in CWWIN Floor’s lineup, the CWWIN-C100 cement-core raised access flooring outperforms traditional wood-core or fibre-board alternatives in high-humidity regions. Crafted from a precision blend of silicate, modified inorganic fibres, and quartz sand, it targets the root causes of flooring failure in moisture-prone areas.

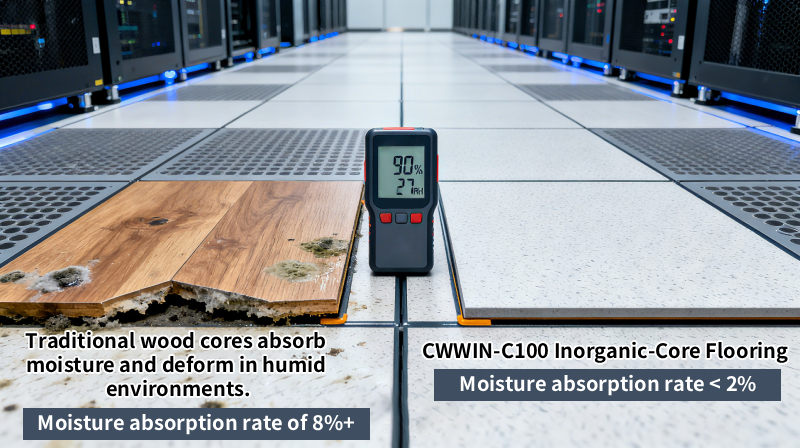

1. Inorganic Core: Minimal Moisture Absorption, Maximum Protection

Unlike wood-core floors that absorb 8%+ moisture in humid conditions, the CWWIN-C100 achieves <2% moisture absorption over 72 hours (tested at 90% relative humidity [RH], per ASTM D3203 standards). This low absorption rate prevents warping, delamination, and mold growth—critical for data centers and server rooms where equipment integrity is non-negotiable. Additionally, the CWWIN-C100 is SGS-certified for zero formaldehyde and low volatile organic compounds (VOCs), aligning with LEED v4.1 criteria to support green building goals.

2. Dimensional Stability: Consistent Performance Year-Round

Daily humidity fluctuations often cause flooring to expand or crack, but the CWWIN-C100’s advanced manufacturing process ensures <0.5mm annual deformation (surpassing MFMA 2025 requirements). Real-world deployments in South China’s plum rain season and South Korea’s humid summers show even better results, with deformation as low as 0.3mm–0.4mm, thanks to rigorous post-production humidity cycling tests.

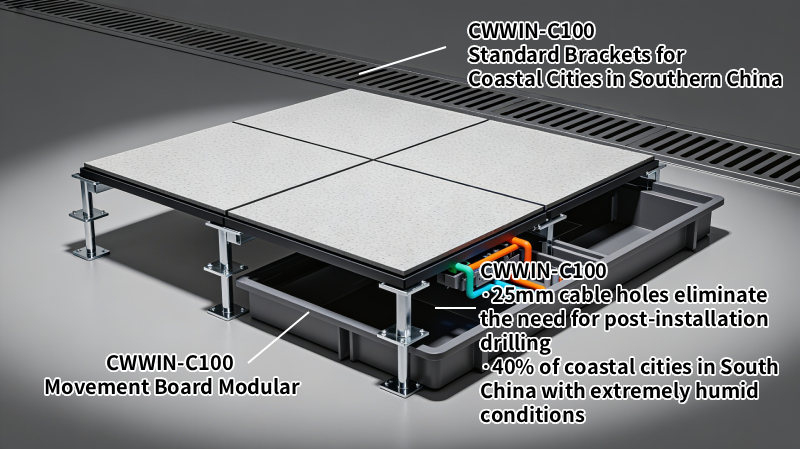

3. Modular Design: Enhanced Ventilation & Easy Maintenance

The CWWIN-C100’s raised structure (combining panels, pedestals, and under-floor cavities) reduces condensation by 40% when paired with proper ventilation (per USGBC data). Pre-drilled 25mm cable holes eliminate post-installation drilling— a common source of moisture entry. For extreme humidity areas like South China’s coastal cities, the system is compatible with industry-standard drainage-groove pedestals to further manage moisture.

Practical Maintenance Guidelines for Humid Regions

To maximize the CWWIN-C100’s lifespan and minimize moisture risks, CWWIN Floor recommends these actionable practices, aligned with its project support expertise:

1. Control Under-Floor Humidity

• Moderate humidity (e.g., South Korea’s Incheon, U.S. Houston): Install 1 passive vent per 100 sq. ft. to promote natural airflow, a design that integrates seamlessly with the CWWIN-C100 system.

• Extreme humidity (e.g., South China’s Guangzhou, U.S. coastal Louisiana): Deploy 50–70 pint/day dehumidifiers alongside drainage-groove pedestals to manage groundwater rise.

• Pre-installation prep: Conduct slab moisture testing via ASTM F2170 (in-situ RH test) to ensure <75% RH before installation. For low-lying areas like South China’s Pearl River Delta, use a 10-mil vapor barrier (ASTM E1745 Class A) to block groundwater intrusion—CWWIN Floor offers on-site testing support for Asian clients.

2. Regular Cleaning & Inspections

• Daily: Use a soft-bristle vacuum attachment to remove grit that can scratch the CWWIN-C100’s protective coating.

• Weekly: Perform static mopping with a pH-neutral cleaner (avoid ammonia) to preserve anti-moisture seals.

• Quarterly: Inspect panel edges for lifting or staining, and check pedestal bolts for looseness.

• Annually: Examine stringers for corrosion (critical in coastal areas) and reapply industry-approved edge sealant every 2–3 years.

3. Emergency Response to Water Incidents

Hidden moisture causes 80% of premature flooring failures (per ICC 2024). Follow this verified protocol:

1. Remove wet CWWIN-C100 panels within 24 hours.

2. Dry the under-floor cavity with industrial fans (50 CFM per 100 sq. ft.).

3. Test panels with a moisture meter (ASTM D4442)—discard if moisture exceeds 15%.

4. Replace corroded pedestals/stringers (rust reduces load capacity by 20%).

5. Document the incident for compliance.

Case Example: In 2023, a Shenzhen data center using the CWWIN-C100 faced 30mm rainfall-induced groundwater rise. By following this protocol, only 2 panels were replaced—cutting repair costs by 75% compared to wood-core floors (consistent with CWWIN’s official website case showcase).

Cement-Core vs. Alternative Flooring: Long-Term Value Comparison

For humid-region facilities, long-term value matters more than upfront cost. The CWWIN-C100 stands out across key metrics:

|

Flooring Type

|

Moisture Absorption

|

Annual Maintenance Cost

|

10-Year Lifespan

|

Key Advantages of Cement-Core Flooring

|

|

CWWIN-C100 Cement-Core

|

<2%

|

$1.20–$1.80/sq. ft.

|

90–95%

|

3-year moisture warranty (matches official website terms); easy integration with modular systems

|

|

Calcium Sulphate

|

<2.5%

|

$1.40–$2.00/sq. ft.

|

85–90%

|

Lower maintenance cost; better compatibility with Asian project timelines

|

|

Steel Anti-Static

|

<1.5%

|

$1.60–$2.20/sq. ft.

|

85–90%

|

More cost-effective for long-term use; no PVC off-gassing

|

|

Wood-Core

|

>8%

|

$2.50–$3.20/sq. ft.

|

50–60%

|

No warping; 60% fewer repairs vs. wood-core (per official website data)

|

|

Vinyl/LVP

|

3–5%

|

$0.80–$1.20/sq. ft.

|

70–80%

|

Under-floor access for cable management; no edge lifting

|

Integrated System Recommendations for Complex Facilities

For complex facilities (e.g., South Korean electronics plants, U.S. data centers), a hybrid approach optimizes performance. This modular design not only reduces compatibility risks but also aligns with industry best practices:

• Main areas: Cement-core raised access flooring (moisture resistance + under-floor access)

• Equipment zones: Ventilated panels (adjustable airflow: 20–40%) for heat dissipation

• Electronics areas: Anti-static panels (compatible with cement-core pedestals)

Installation & Long-Term Cost Optimization for Cement-Core Flooring

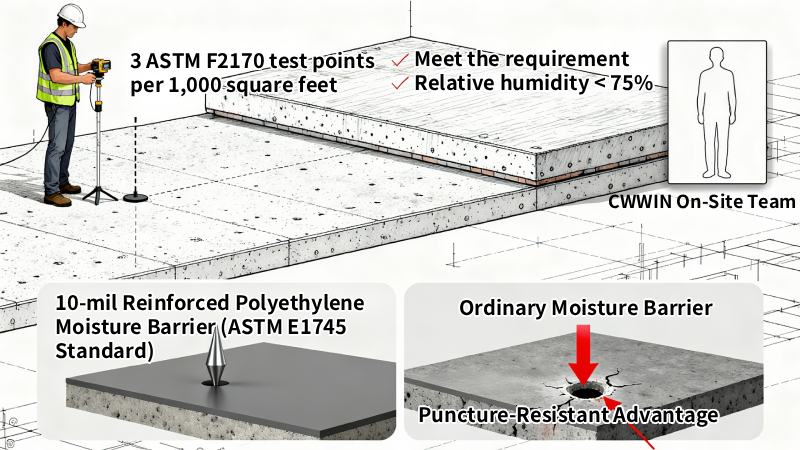

1. Pre-Installation: Avoid Common Pitfalls

• Conduct thorough slab testing (3 ASTM F2170 locations per 1,000 sq. ft.), as failed tests account for 60% of moisture-related issues. Ensure slab RH meets the <75% pre-installation requirement (detailed in Chapter 3). For Asian clients, CWWIN’s on-site team supports this step.

• Choose reinforced polyethylene vapor barriers (10-mil, ASTM E1745) over generic options to prevent punctures.

2. Installation: Timing & Precision

• Install only when ambient RH is 40–60% and temperature is 65–75°F (18–24°C). Avoid South China’s May–August plum rain season and U.S. Gulf Coast’s June–September rains.

• Maintain pedestal height tolerance of ±0.8mm (exceeding ASTM F710’s ±1mm standard) to prevent moisture trapping at seams.

3. Long-Term Savings Strategies

• Place 3-foot-wide moisture-absorbent mats at entryways—reduces tracked-in humidity by 20% (per official website Miami case data).

• Pair under-floor ventilation with smart sensors to cut dehumidifier costs by $0.12/sq. ft. annually.

• Leverage the 3-year moisture warranty (detailed in Chapter 4) to minimize repair risks.

Partner for Humid-Region Flooring Success

CWWIN Floor delivers end-to-end support for cement-core raised access flooring projects, including site assessments, turnkey installation solutions (as referenced on the official website), and 24/7 technical assistance. With local warehousing in South Korea and China, we ensure timely delivery and emergency support for Asian clients. For U.S. customers, streamlined logistics via authorized partners meet project timelines.

To learn more about cement-core raised access flooring or request a sample (as offered on the official website), contact CWWIN Floor today.