US Raised Access Floors: 5-Step Guide to CISCA Compliance & Material Selection (2025)

- Addtime: 2025-10-24 / View: 207

In today’s fast-paced environments—from high-performance data centers and bustling telecommunications hubs to advanced intelligent offices—raised access floor panels are indispensable. They serve as the backbone for ensuring long-term operational reliability, workplace safety, and cost efficiency. For project teams tasked with designing medium-density data halls, critical telecom rooms, or heavy-duty equipment zones, two pressing challenges often arise: aligning panel performance with global standards (to support cross-regional projects) and matching material properties to site-specific conditions, such as humidity levels and equipment load requirements.

This guide dives deep into two leading raised access floor technologies: calcium sulfate core panels and cement/steel-shell core panels. It breaks down their technical specifications, performance advantages, and ideal use cases, with a strong focus on load-deflection behavior, moisture resistance, and compliance with key standards like the U.S. CISCA (2023) and European EN 12825. By the end, readers will have a clear, step-by-step framework to select the right panel for their project, supported by actionable data and real-world examples.

1. Core Materials & the Critical Role of International Standards

A standard raised access floor system comprises four key components, each contributing to its overall performance:

• Top Covering: High-Pressure Laminate (HPL), vinyl, or ceramic tile (customizable via official finish options; details available on the brand’s website).

• Structural Shell: 0.8–1.2mm galvanized steel (anti-corrosive, compliant with ISO 1461 standards).

• Internal Core Material: The primary factor influencing load capacity, moisture resistance, and dimensional stability.

• Pedestal/Stringer System: Adjustable steel pedestals (height range: 60–1200mm; load rating: 1200–3000kg) paired with galvanized stringers (per official understructure specifications).

Why Standards Ensure Consistency Across Regions

High-performance raised access floor panels are engineered to meet dual international standards, eliminating discrepancies in cross-regional projects:

U.S. CISCA (2023)

Complies with the Recommended Test Procedures for Access Floors, including:

• Uniform Static Load: Minimum 1000lb/sqft for data center-grade applications.

• Concentrated Load: 500lb at a 2” diameter, with deflection ≤0.05”.

• Rolling Load: 1000lb wheel, 10,000 cycles, and no permanent deformation.

European EN 12825

Classifies systems by ultimate load (e.g., Class 3: 30kN/m²) and deflection (e.g., Class A: ≤2mm under service load), with strict tolerances for:

• Panel Flatness: ≤0.5mm/m.

• Interchangeability: ±0.3mm for panel edge alignment.

• Fire Resistance: EN 13501-1 Class B-s1, d0 (applicable to all core types).

Source: 2025 Technical Datasheet (TDS-RAF-001) | Available at www.cwwinfloor.com/technical-docs

2. Calcium Sulfate Core Panel Series (Models: CS-80/CS-100)

Technical Specifications

|

Parameter

|

CS-80 (80mm Thickness)

|

CS-100 (100mm Thickness)

|

|

Panel Size

|

600x600mm / 600x1200mm

|

600x600mm / 600x1200mm

|

|

Core Density

|

1.8–2.0 g/cm³

|

1.8–2.0 g/cm³

|

|

Static Load Capacity

|

1500lb/sqft

|

2000lb/sqft

|

|

Deflection (Under Load)

|

≤0.04” (at 1500lb/sqft)

|

≤0.03” (at 2000lb/sqft)

|

|

Weight

|

32kg/m²

|

40kg/m²

|

|

Fire Rating

|

EN 13501-1: B-s1, d0

|

EN 13501-1: B-s1, d0

|

Key Performance Strengths

• Anti-Deformation: The dense, inorganic, non-combustible gypsum core is fully enclosed in galvanized steel, eliminating “load creep” (permanent deformation under long-term stress). Testing shows it maintains flatness for over 10 years in data center environments (Case Study: Telecom Italia, 2022).

• Moisture Resistance: Unlike wood-core panels, the inorganic core resists swelling and delamination. Per EN 12825 testing: 72-hour exposure to 95% relative humidity (RH) at 40°C, with dimensional change ≤0.1% and no edge lifting or core damage.

• Easy Installation: Lighter weight (32kg/m² for CS-80) reduces labor costs. It is compatible with quick-lock pedestal systems, enabling installation speeds of 150–200 sqft/hour.

Ideal Applications

• Data halls (medium-density server racks: ≤10kW/rack).

• Telecom rooms (ODF/DDF cabinets, moderate cable loads).

• Intelligent offices (open-plan workstations, underfloor HVAC systems).

3. Cement/Steel-Shell Core Panel Series (Models: CM-100/CM-120)

Technical Specifications

|

Parameter

|

CM-100 (100mm Thickness)

|

CM-120 (120mm Thickness)

|

|

Panel Size

|

600x600mm / 600x1200mm

|

600x600mm / 600x1200mm

|

|

Core Composition

|

Portland cement + fly ash (2.2–2.4 g/cm³ density)

|

Portland cement + fly ash (2.2–2.4 g/cm³ density)

|

|

Static Load Capacity

|

3000lb/sqft

|

4000lb/sqft

|

|

Deflection (Under Load)

|

≤0.02” (at 3000lb/sqft)

|

≤0.015” (at 4000lb/sqft)

|

|

Weight

|

55kg/m²

|

66kg/m²

|

|

Fire Rating

|

EN 13501-1: A2-s1, d0

|

EN 13501-1: A2-s1, d0

|

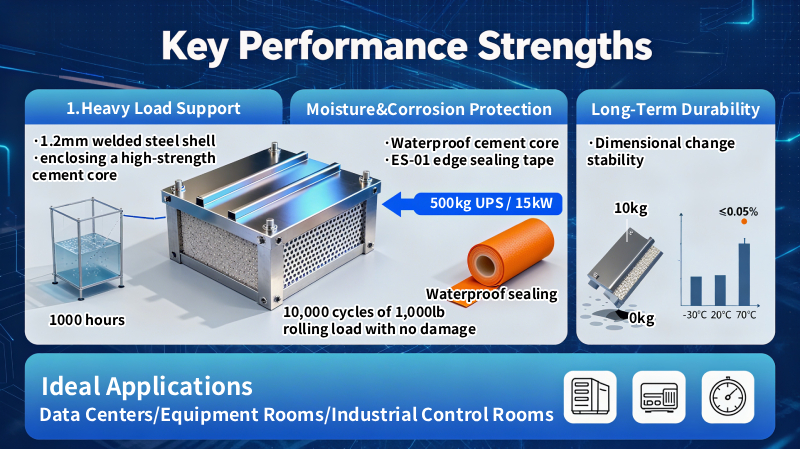

Key Performance Strengths

• Heavy Load Support: A 1.2mm welded steel shell, combined with a high-strength cement core, handles heavy equipment (e.g., 500kg UPS units, 15kW high-density racks) with minimal deflection. CISCA testing confirms: 10,000 cycles of 1000lb rolling load, with no structural damage.

• Moisture & Corrosion Protection: The steel shell features zinc-nickel plating (1000-hour salt spray test, no rust), and the cement core includes waterproof admixtures. For wet environments (e.g., data centers with underfloor water cooling), edge-sealing tape (part no. ES-01) is recommended to block vapor ingress.

• Long-Term Durability: Resists impact (10kg drop from 1m, no core cracking) and temperature fluctuations (-30°C to 70°C, dimensional change ≤0.05%).

Ideal Applications

• Heavy-duty data centers (high-density racks: ≥15kW/rack, raised cold aisles).

• Equipment rooms (generators, transformers, 2000lb-capacity rolling carts).

• Industrial control rooms (dust, temperature variations, heavy instrumentation).

4. Side-by-Side Comparison: CS Series vs. CM Series

|

Criteria

|

Calcium Sulfate Core (CS Series)

|

Cement/Steel-Shell Core (CM Series)

|

|

Load Capacity

|

1500–2000lb/sqft (CISCA compliant)

|

3000–4000lb/sqft (CISCA Heavy-Duty; EN 12825 Class 4)

|

|

Deflection (Service Load)

|

≤0.04” (CS-80) / ≤0.03” (CS-100)

|

≤0.02” (CM-100) / ≤0.015” (CM-120)

|

|

Moisture Resistance

|

Excellent (≤0.1% change at 95% RH)

|

Superior (zinc-nickel plating + waterproof core)

|

|

Weight

|

32–40kg/m² (lighter, lower slab load)

|

55–66kg/m² (heavier; requires ≥200kg/sqft slab capacity)

|

|

Fire Rating

|

EN 13501-1: B-s1, d0

|

EN 13501-1: A2-s1, d0 (non-combustible)

|

|

Installation Cost

|

Lower (faster labor, no heavy lifting gear)

|

Higher (requires heavy lifting equipment)

|

|

Model Details

|

CS-80/CS-100 (see official calcium sulfate page)

|

CM-100/CM-120 (see official cement/steel-shell page)

|

5. Step-by-Step Selection Guide

Step 1: Define Load Needs

• Calculate the maximum static load (e.g., server racks, equipment) using the official load calculator (available on the website).

• For rolling loads ≥1000lb (e.g., carts, forklifts), specify the CM Series.

Step 2: Assess Site Conditions

• If humidity >60% or underfloor water cooling is used: Choose the CM Series (zinc-nickel plating ensures enhanced protection).

• For moderate humidity (40–60%): Opt for the CS Series (cost-effective and reliable).

Step 3: Confirm Standard Compliance

• For U.S. projects: Request the CISCA test report (Document No. CIS-2025-007).

• For European projects: verify the EN 12825 classification (e.g., CM-120: Class 4/A/1).

Step 4: Check Structural Fit

• For the CM Series: Ensure the building slab can support a dead load of ≥200kg/sqft.

• Pair panels with compatible pedestals (P-800 for the CS Series, P-1200 for the CM Series).

Step 5: Finalize Finishes & Accessories

• Select the top covering using the official finish selector (HPL for anti-static needs, vinyl for anti-slip requirements).

• Add essential accessories: cable grommets (CG-02), edge ramps (ER-01).

Calcium sulfate (CS Series) and cement/steel-shell (CM Series) raised access floor panels are engineered to meet global standards (CISCA, EN 12825), ensuring consistent performance across international projects. The CS Series delivers balanced performance and cost efficiency for medium loads and moderate humidity, while the CM Series offers unmatched durability for extreme loads and harsh environments. By following the step-by-step selection guide, project teams can confidently choose the panel that aligns with their specific needs—ultimately enhancing operational reliability and long-term cost savings.