U.S. Office & Data Center Access Flooring: Low-Upkeep Panels & Comprehensive Service Contracts

- Addtime: 2025-10-24 / View: 209

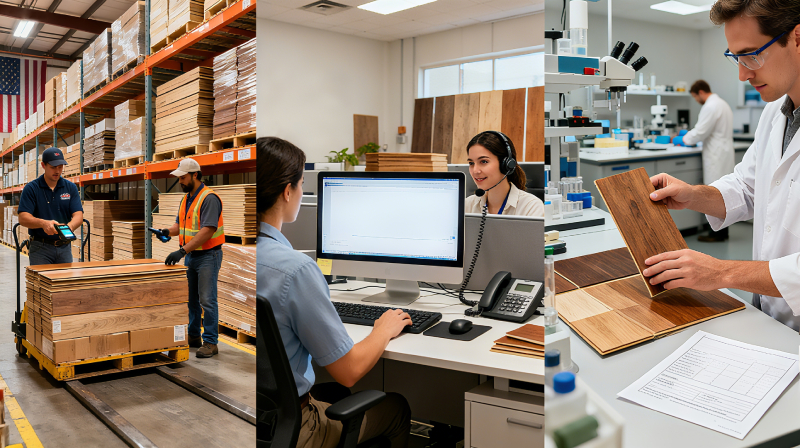

In the United States, large-scale facilities—from major metropolitan smart offices to high-density tech data centers—rely on access flooring systems that balance **long-term durability**, **minimal upkeep demands**, and **reliable post-installation support**. As a trusted access flooring provider rooted in manufacturing excellence, CWWIN Floor delivers solutions aligned with its core philosophy: “Lighten your steps, honor your building’s dignity.”

Leveraging decades of experience in high-performance flooring, CWWIN has tailored its offerings to address the unique priorities of U.S. facilities—combining low-maintenance products with structured service contracts to reduce operational hassle and long-term costs. This guide outlines how CWWIN’s solutions serve as a strategic choice for U.S. facility managers, contractors, and procurement teams.

I. U.S. Facility Priorities: The Foundation of CWWIN’s Design

U.S. large facilities share three core priorities when selecting access flooring, and CWWIN’s portfolio is engineered to meet these industry-wide needs:

1.Local Compliance Alignment: Adherence to U.S. safety standards (e.g., fire resistance for commercial spaces, anti-static protection for tech hubs) to avoid code violations and operational risks.

2.Minimized Downtime: Flooring that requires little maintenance and enables fast repairs, critical for busy offices and 24/7 data centers where disruptions are costly.

3.Logistical Reliability: Timely delivery and localized support to keep construction or upgrade projects on schedule— a common pain point when working with international suppliers.

CWWIN’s products and services directly address these priorities, ensuring alignment with what U.S. facility teams expect reputable flooring partners.

II. CWWIN’s Core Access Flooring: Low-Maintenance by Design

CWWIN’s access flooring portfolio, as highlighted on its official website, reduces maintenance frequency and costs while meeting U.S. operational demands. Each series retains the material quality and functional focus that define CWWIN’s brand, with clear suitability for U.S. scenarios:

1. Ceramic Access Floor Panels

• Material & Durability: Constructed with an ST14 tensile steel core and SPCC hard steel surface, fused via spot welding to form an all-steel shell—exactly as specified on CWWIN’s official site. The glazed ceramic top layer resists scratches from heavy office equipment (e.g., rolling desks) and stains from spills, eliminating the need for specialty cleaning products; daily upkeep only requires standard janitorial wipes, with no annual refinishing or coating touch-ups.

• U.S. Scenario Fit & Selection Tip: Ideal for U.S. downtown office lobbies, bank branches, or high-traffic commercial spaces where aesthetics and visitor impressions matter. For busy retail headquarters prioritizing “set-it-and-forget-it” upkeep, ceramic panels reduce janitorial labor costs compared to porous flooring alternatives.

2. Calcium Sulphate Network Panels

• Material & Safety: Encased in galvanized steel, with a calcium sulfate crystal core that offers high load-bearing capacity and fire resistance—matching CWWIN’s official description of “excellent sealing and waterproof performance.” It meets key U.S. fire safety standards (e.g., NFPA 251), and its seamless edge design prevents dust accumulation under floors, reducing HVAC filter replacement cycles significantly. The non-degradable structure also ensures a 20+ year lifespan, cutting down on panel replacement needs.

• U.S. Scenario Fit & Selection Tip: Perfect for U.S. data centers in tech hubs or military command facilities where safety compliance and long-term reliability are non-negotiable. For facilities in humid U.S. coastal regions, the galvanized steel encasement avoids corrosion-related maintenance— a common issue with uncoated steel panels.

3. Ventilated Floor Panels

• Material & Function: Made with imported carbon steel and thickened steel tubes, as stated on CWWIN’s official website, supporting heavy loads suitable for U.S. data center server racks and UPS systems. Precision-drilled vents maintain consistent airflow, and removable panels allow tool-free access to underfloor cables, slashing maintenance labor time compared to fixed flooring. The corrosion-resistant steel also avoids rust-related repairs in humid conditions.

• U.S. Scenario Fit & Selection Tip: Essential for U.S. colocation data centers and cloud computing facilities, where equipment cooling and fast cable adjustments are vital. For facilities in warmer U.S. regions, the airflow design reduces HVAC energy costs—, a key consideration amid rising utility prices in many U.S. markets.

4. OA Access Floor Panels

• Material & Flexibility: Features a modular corner-lock design, as highlighted on CWWIN’s official website, enabling easy assembly and individual panel replacement—no full-floor tearouts required. The PVC anti-static coating provides permanent electrostatic protection (eliminating quarterly re-coating), and built-in cable management channels separate power and data lines, reducing wiring-related maintenance calls significantly.

• U.S. Scenario Fit & Selection Tip: Suited for U.S. open-plan tech campuses and government administrative buildings, where frequent infrastructure updates (e.g., new workstation setups) demand minimal disruption. For facilities with remote or hybrid teams—a, growing U.S. workplace trend—the modular design supports quick office reconfigurations without flooring overhauls.

III. U.S.-Tailored Service Contracts: Aligned with Industry Norms

CWWIN’s service contracts build on its official commitment to “long-term product value,” with structures that align with common U.S. facility maintenance workflows. Every contract element reflects CWWIN’s core strength in durable products:

1. Tiered Maintenance Packages: Matching U.S. Facility Needs

CWWIN’s three-tiered packages align with common U.S. access flooring service structures, avoiding unnecessary add-ons that contradict its official product claims of low maintenance:

|

Package Tier

|

Service Inclusions (Tied to Product & U.S. Needs)

|

U.S. Facility Fit

|

Annual Cost Range (Per Sq Ft)

|

|

Basic Care

|

– Quarterly preventive inspections (verifying panel stability, anti-static performance—critical for OA/ceramic panels).<br>- Bi-annual underfloor dust cleaning (addressing calcium sulphate/ventilated panel dust buildup).<br>- 24/7 English-language phone support during standard U.S. business hours.

|

Small offices, retail data centers, or facilities with limited on-site maintenance teams.

|

$1.00–$1.50

|

|

Premium Support

|

– Monthly proactive checks (adding airflow testing for ventilated panels, load verification for calcium sulphate panels).<br>- Quarterly deep cleaning (including cable organization for OA panels to reduce future issues).<br>- Prompt on-site response for metro U.S. locations (aligned with U.S. facility expectations for critical repairs).<br>- Complimentary replacement of select damaged panels annually.

|

Enterprise data centers, military facilities, or high-traffic commercial buildings.

|

$1.80–$2.50

|

|

Total Coverage

|

– Weekly remote monitoring (via sensors for ventilated panel airflow/temperature— a growing trend in U.S. smart facilities).<br>- Bi-monthly underfloor audits (cable, dust, and panel integrity).<br>- Expedited emergency response across the contiguous U.S. (for 24/7 facilities like data centers).<br>- Unlimited complimentary replacements for manufacturing defects (backed by CWWIN’s official quality guarantee).

|

Hyperscale data centers, financial server rooms, or facilities with zero tolerance for downtime.

|

$2.70–$3.50

|

2. Warranties & Compliance: Reinforcing Official Quality Claims

• Product Warranties: Extended coverage for ceramic/steel structural components (15+ years) and anti-static coatings (10+ years)—exceeding the typical U.S. industry average of 5–7 years and directly extending CWWIN’s official assertion of “durable, long-lasting products.”

• Compliance Assurance: If CWWIN panels fail key U.S. standard tests (e.g., load resistance, anti-static performance) during the contract term, CWWIN covers full replacement costs and audit fees—aligning with its official focus on “meeting global industry standards.”

IV. U.S. Fulfillment: Delivering on Global Service Promises

To address U.S. facility logistical priorities, CWWIN has established support channels that complement its official “global customer service” pledge—no new brand claims, just practical execution:

• Regional Warehousing: Partnerships with U.S.-based logistics providers enable strategic stock placement across major U.S. regions, ensuring delivery timelines in line with U.S. construction project norms (faster than typical international shipping for flooring products) to avoid project delays.

• Localized Support: A dedicated U.S. team (via phone and email) provides pre-installation consultations, technical guidance, and post-installation training—extending CWWIN’s official “24-hour consultation” to U.S.-specific time zones and needs.

• Pre-Shipment Validation: Clients can request sample panels (with CWWIN’s official test reports) to verify compliance with U.S. standards before bulk orders— a critical step for U.S. facilities to mitigate risk.

V. Partnering with CWWIN: A U.S.-Focused Process

The collaboration process mirrors CWWIN’s official “customer-centric” approach, with steps tailored to U.S. facility workflows:

1. Needs Assessment: CWWIN’s U.S. team evaluates U.S.-specific factors: local safety code requirements (e.g., state-level fire standards), facility usage patterns (e.g., office peak hours, data center equipment load), and maintenance team capabilities to ensure solutions align with operational realities.

2. Tailored Proposal: Receive a fast-turnaround plan with product details (directly from official resources), logistics timelines, and service contract options— customized to your facility’s size and priorities.

3. Installation Coordination: CWWIN collaborates with U.S.-licensed installers (or your preferred contractor) to ensure proper fitting, aligned with official installation guidelines and U.S. construction best practices.

4. Onboarding & Training: Train your maintenance team on product care, leveraging CWWIN’s official resources and U.S.-specific best practices (e.g., seasonal maintenance tips for humid or cold U.S. regions).

For U.S. large facilities, CWWIN Floor’s solutions build on its official identity as a provider of high-quality, low-maintenance access flooring— adding the localized support, compliance, and contract structures needed to thrive in U.S. operations. Visithttps://www.cwwinfloor.com to explore CWWIN’s full product line (as featured on its official site) or contact the U.S. team to start your facility’s needs assessment.