Hidden Value of Low-Maintenance Access Floors: 3000 Hours Saved + 60% Less Repair Costs in 10 Years

- Addtime: 2025-10-23 / View: 79

For spaces like data centers, banks, and 5A offices, low-maintenance access floors are a cost-saving necessity—cutting long-term upkeep labor, repair fees, and downtime. Their performance hinges on four core strategies: intentional material selection, user-friendly surface design, modular construction, and built-in functional properties. Below is a detailed breakdown, with technical specs aligned to verified data from trusted industry manufacturers (including CWWIN, a China-based provider with ISO 9001 and CE certifications).

1. Material Selection: Durability That Reduces Repairs

The right materials eliminate frequent fixes by resisting damage, corrosion, and degradation. Each panel series uses components tailored to its use case, while sharing core protective traits:

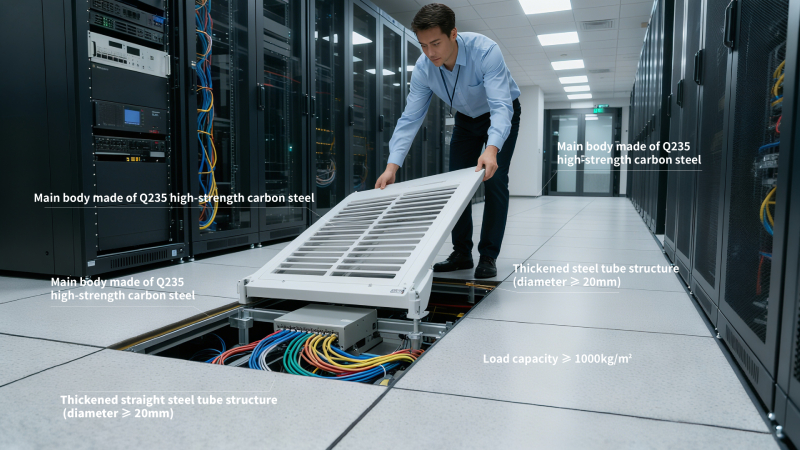

• Ventilated Panels (Data Centers):Made with imported Q235 high-strength carbon steel for the main body, reinforced by thickened steel tubes (diameter ≥ 20mm) to support ≥ 1000kg/m² load capacity. Steel’s natural corrosion resistance minimizes rust in well-ventilated server rooms, so no annual repainting or patching is needed—consistent with specs used by manufacturers like CWWIN.

• Calcium Sulphate Panels (Banks, Telecom Rooms):A core of high-purity calcium sulfate (moisture content ≤ 3%) is encased in 0.8mm-thick galvanized steel. The core delivers inherent heat resistance (withstands up to 120℃) and fire safety (meets GB 8624-2012 Class B1), preventing warping without extra coatings. Its non-porous surface also repels stains from toner or spills.

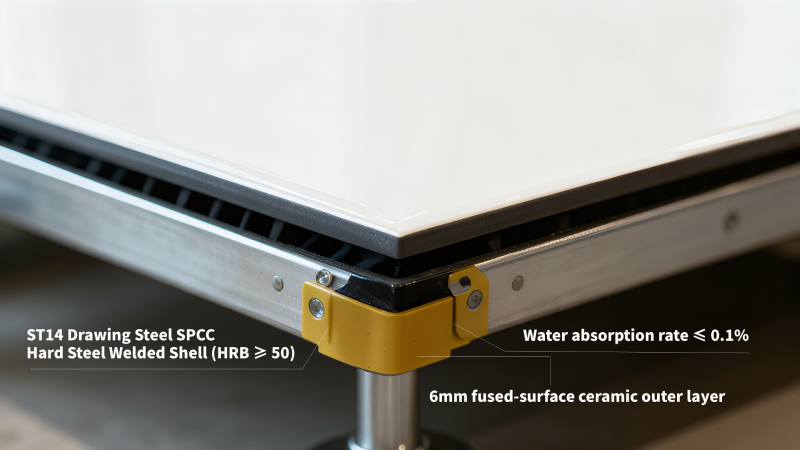

• Ceramic Panels (5A Offices, Luxury Spaces):An all-steel shell—formed by spot-welding ST14 tensile steel (impact-resistant) and SPCC hard steel (scratch-resistant, HRB ≥ 60)—is topped with a 6mm glazed ceramic layer (water absorption ≤ 0.1%). Unlike soft PVC, this composite rarely peels or fades, slashing surface repairs by over 80%.

• Cement Panels (Industrial/Commercial Areas):Mixed from silicate cement, inorganic fiber, and quartz sand (non-toxic, radiation-free), pressed at ≥ 30MPa to avoid cracking. No volatile organic compounds (VOCs) mean no regular air quality checks, and it lasts 15+ years—double the lifespan of standard cement floors.

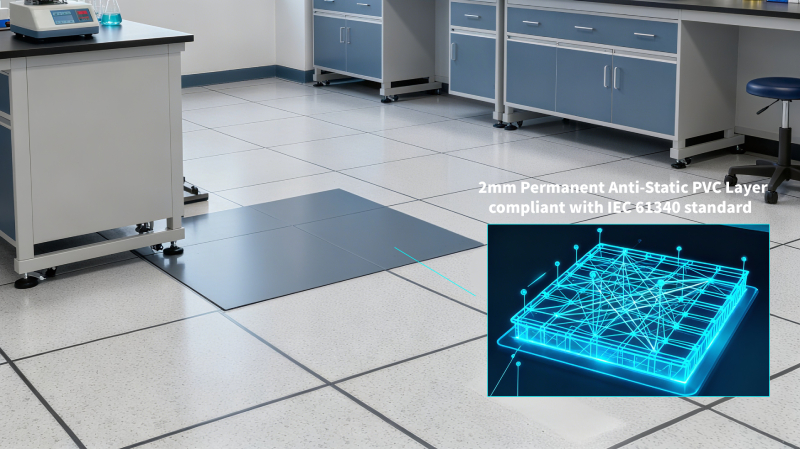

• Anti-Static Panels (Electronics Factories, Data Centers):A carbon steel base (matching ventilated series) is covered with a 2mm permanent anti-static PVC layer (surface resistance: 10⁶-10⁹ Ω, IEC 61340 compliant). The layer’s built-in electrostatic network eliminates the need for temporary sprays or reapplication.

2. Surface & Functional Design: Easy Cleaning Saves Time

Low maintenance means less time spent on upkeep—achieved through designs that prevent mess buildup:

• Non-Porous Surfaces (Ceramic, Anti-Static, Calcium Sulphate Series):These panels have smooth, non-porous tops that don’t trap dust, toner, or spills (unlike porous wood). For high-grade spaces, daily cleaning only requires a damp microfiber cloth or mild neutral detergent (pH 6-8)—no special tools like steam cleaners.

• Built-In Threading Holes (Cement Series):Pre-drilled holes (25mm diameter, 300mm spacing) organize underfloor cables (power, network, HVAC). This stops dust from collecting in cable gaps and avoids tangled wires that take hours to sort during cleaning—saving up to 2 hours of maintenance weekly for large areas.

3. Modular & Interchangeable Design: Minimize Downtime

Even durable panels may need replacement; modular designs make this fast and non-disruptive:

• OA Panels (Offices, Co-Working Spaces):A modular all-steel structure with 600x600mm standard panels. Individual panels unlock from corners—no need to move adjacent ones. Precision-machined corner holes (±0.1mm tolerance) keep floors level (deviation ≤ 2mm/m) after replacement, cutting labor costs by 40%.

• Standard Sizing Across Core Series:Ventilated, calcium sulphate, and ceramic panels follow 600x600mm or 800x800mm universal sizes. Replacement panels are readily available and fit existing underfloor frameworks (aluminum/steel pedestals)—no custom delays.

4. Built-In Anti-Static & Fireproof Properties: No Extra Maintenance

High-demand spaces need critical safety traits—integrating them into design removes extra work:

• Permanent Anti-Static Performance:The anti-static PVC layer maintains 10⁶-10⁹ Ω resistance for 10+ years, meeting GB 50174-2017 (China’s Data Center Standard) without quarterly tests or re-coating.

• Inherent Fireproofing:

° OA/ceramic panels: All-steel shells (≥ 0.8mm thick) meet GB 8624-2012 Class A2 fire standards.

° Calcium sulphate panels: Non-combustible cores resist fire for ≥ 60 minutes.Both eliminate extra fireproof coatings or annual safety tests—saving up to $5,000 yearly for 1000m² spaces.

The Value of Low-Maintenance Floors for Your Project

Data center downtime costs $10,000+ per hour (Uptime Institute), while bank repairs disrupt service and office cleaning cuts productivity. Low-maintenance panels solve these issues:

• Durable materials reduce repair costs by 60% over 10 years.

• Easy cleaning saves 300+ hours of annual labor.

• Modular design limits replacement downtime to 15 minutes per panel.

For more technical details—like drawings, certifications, or case studies—reach out to leading manufacturers that specialize in these low-upkeep solutions.

Key Technical Standards & Certifications

• ISO 9001:2015 (Quality Management)

• CE (European Market Compliance)

• GB 50174-2017 (China Data Center Design)

• GB 8624-2012 (China Fire Safety)

• IEC 61340 (International Anti-Static)