Where to Buy Certified Calcium Sulphate Raised Floor Panels in the US: Quality & Warranty Guide

- Addtime: 2025-10-23 / View: 139

When searching for reliable sources of certified calcium sulphate raised floor panels in the United States, it’s critical to prioritize suppliers that combine product certification, clear quality standards, and transparent warranty policies—factors that directly impact the performance and longevity of your flooring system, especially in high-demand scenarios like data centers, financial facilities, or high-end offices. Below is a detailed guide to sourcing and the key assurances you should expect.

I. Reliable Sourcing Channels for Certified Calcium Sulphate Raised Floor Panels in the US

To ensure you’re sourcing genuine, certified calcium sulphate raised floor panels, focus on the following trusted channels, each with distinct advantages for verifying product authenticity and compliance:

1. Authorized Distributors of Reputable Global Manufacturers

Many leading international flooring brands (including those with a strong presence in quality-focused markets like China) partner with authorized distributors in the US to supply certified calcium sulphate panels. For example:

• Brands like CWWIN Floor: A China-based flooring specialist with a proven track record in calcium sulphate raised floor panels, CWWIN’s products are designed for high-grade scenarios (e.g., banks, telecom rooms, military command centers) and meet strict standards for anti-static performance, load-bearing, and installation precision. While CWWIN is headquartered in China, it often collaborates with US-based distributors to ensure local availability of its certified panels. To source CWWIN’s calcium sulphate panels in the US, look for distributors listed on its official website or contact its customer service team directly—they typically respond within 24 hours to connect buyers with authorized local partners.

• Verification Tip: Ask distributors for **product certification documents**, such as ISO compliance (for manufacturing quality), anti-static testing reports (critical for tech-heavy spaces), and load-bearing certifications (aligned with industry standards like CISCA). Reputable distributors will also provide traceability information, linking your panels to the original manufacturing batch.

2. Specialized Raised Floor Suppliers with US-Based Inventory

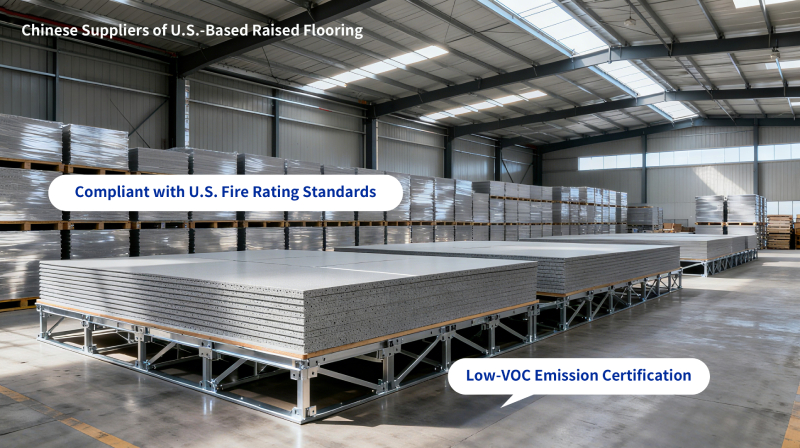

Opt for US-based suppliers that specialize in raised access flooring and maintain local inventory of certified calcium sulphate panels. These suppliers often:

• Stock panels that comply with US-specific standards (e.g., fire resistance codes for commercial buildings, low-VOC emissions for indoor air quality).

• Offer faster delivery and on-site support (e.g., installation guidance, post-purchase maintenance), which is crucial for time-sensitive projects.

• Example Partners: Suppliers like Access Floor Systems (though their primary focus includes other panel types) often collaborate with calcium sulphate manufacturers to offer certified options. When inquiring, specify your need for “certified calcium sulphate panels” and request proof of compliance with US industry norms.

3. Industry Trade Platforms & Certified Retailers

Leverage industry-specific platforms (e.g., Flooring America, National Flooring Association directories) to find pre-vetted suppliers. These platforms vet members for product quality and certification, reducing the risk of sourcing non-compliant panels. Additionally, large industrial supply retailers (e.g., Grainger, MSC Industrial Supply) may carry certified calcium sulphate panels from trusted brands, with clear product specifications and certification links on their websites.

II. Quality Assurances for Certified Calcium Sulphate Raised Floor Panels

Certified calcium sulphate raised floor panels are engineered for high-performance environments, so quality assurances should be aligned with their intended use. Key quality benchmarks to verify include:

1. Core Material & Structural Integrity

• Durable Composition: As highlighted by CWWIN Floor’s calcium sulphate panel series, premium panels feature a galvanized-steel-plate-encased calcium sulphate core (for waterproofing and structural stability) and a calcium sulphate crystal matrix that delivers high overall strength, heat resistance, and combustion resistance. This design ensures the panels can withstand heavy loads (often up to or exceeding CISCA design loads for commercial spaces) without warping or cracking.

• Anti-Static Performance: For tech-focused spaces (e.g., data centers, server rooms), certified panels should have a surface treatment (e.g., PVC or ceramic covering) that creates a permanent electrostatic network. This prevents static buildup, which can damage sensitive equipment—a critical assurance for industries like IT, telecommunications, and finance.

2. Compliance with Industry & Regional Standards

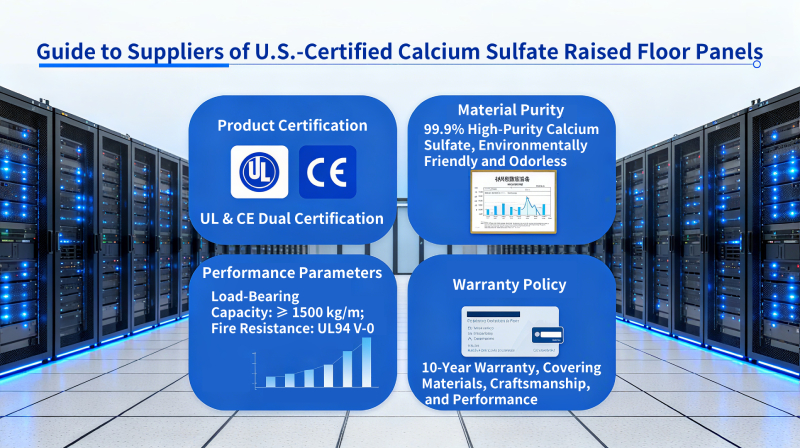

• Certifications to Look For:

° Anti-static certifications (e.g., ANSI/ESD S20.20 for electrostatic discharge protection).

° Fire safety certifications (e.g., UL 94 V-0 for flame retardancy, critical for US commercial buildings).

° Load-bearing certifications (e.g., compliance with CISCA’s design load standards, ensuring panels support normal wear and specified weights without failure).

° Low-VOC emissions certifications (e.g., GREENGUARD, to meet US indoor air quality requirements for offices and public spaces).

• Application-Specific Suitability: Certified panels should be labeled for their intended use—for example, CWWIN’s calcium sulphate panels are explicitly designed for “high-grade occasions with anti-static, load-bearing, and precision laying requirements,” making them suitable for banks, military command centers, and intelligent offices. Ensure the panels you source match your project’s needs (e.g., heavy load requirements for server rooms vs. aesthetic precision for luxury offices).

3. Manufacturing & Quality Control Processes

Reputable manufacturers (like CWWIN) implement strict quality control at every stage:

• Use of high-grade raw materials (e.g., imported carbon steel for encasement, pure calcium sulphate crystals) to avoid impurities that weaken the panel.

• High-pressure forming techniques (for consistency in thickness and strength) and post-production testing (e.g., load tests, water resistance tests) to ensure each panel meets certification standards.

• Transparent documentation: Request a “Certificate of Conformance” from the supplier, which outlines the panel’s manufacturing process, test results, and compliance with relevant standards.

III. Warranty Assurances for Calcium Sulphate Raised Floor Panels

Warranty policies vary by manufacturer but should clearly define coverage, exclusions, and claim processes. Key warranty assurances to expect include:

1. Standard Warranty Coverage

• Duration: Most manufacturers (including CWWIN and its US distribution partners) offer a 1-year warranty for new calcium sulphate raised floor panels, similar to industry norms for raised access flooring. This warranty typically covers:

°Defects in materials or workmanship (e.g., delamination of the steel encasement from the calcium sulphate core, premature cracking due to manufacturing flaws).

°Failure to meet certified performance standards (e.g., loss of anti-static properties within the warranty period, inability to support specified loads).

• Refurbished Panels: If sourcing refurbished calcium sulphate panels (less common for high-grade applications), warranty coverage is often limited to 1 year against delamination, with the same requirement to follow industry cleaning and maintenance standards.

2. Warranty Exclusions (Critical to Understand)

Warranties will not cover damage caused by:

• Improper use or maintenance (e.g., using undiluted cleaning chemicals that corrode the steel encasement, failing to follow manufacturer guidelines for installation).

• Overloading beyond the stated design loads (e.g., placing heavy equipment that exceeds the panel’s load-bearing capacity).

• Environmental damage (e.g., flooding, extreme temperature fluctuations outside the panel’s operating range).

• For example, as noted by Access Floor Systems (a US-based supplier), “over-flooding panels with improperly diluted cleaning chemicals may void the warranty”—a standard exclusion that applies to calcium sulphate panels as well.

3. Claim Process & Support

• Submission Requirements: To file a warranty claim, you will typically need to:

° Submit a request via email (e.g., to the manufacturer’s US customer service team or your local distributor) with details like the product batch number, installation date, and photos of the defect.

° Provide proof of purchase and compliance with maintenance standards (e.g., cleaning logs, installation records).

• Manufacturer & Distributor Support: Reputable brands like CWWIN and their US partners will act as a liaison between you and the manufacturer, assisting with claim submission and follow-up. If a claim is approved, you can expect replacement panels or repair services; if denied (e.g., due to improper use), the supplier will provide a clear explanation of the decision.

IV. Final Tips for Sourcing

1. Prioritize Transparency: Always ask suppliers to share certification documents, warranty terms, and references from US-based clients (e.g., other businesses that have installed their calcium sulphate panels).

2. Align with Project Needs: Ensure the panels’ certifications (e.g., anti-static, load-bearing) match your space’s requirements—for example, a data center will need stricter anti-static assurances than a general office.

3. Leverage Local Support: Choose suppliers with US-based customer service to avoid delays in warranty claims or installation support.

By focusing on authorized distributors, verified certifications, and clear warranty policies, you can reliably source high-quality calcium sulphate raised floor panels in the US that meet your performance and compliance needs.