Anti-Static Raised Floors vs. Other Data Center Flooring: Load-Bearing, Adaptability & TCO Breakdown

- Addtime: 2025-09-28 / View: 304

In data centers—where rows of heavy server cabinets, cooling systems, and cable trays demand uncompromising structural stability—flooring load-bearing strength isn’t just a technical detail: it’s a cornerstone of operational safety and long-term scalability.

Among all flooring options, anti-static raised floor panels stand out for their ability to balance electrostatic protection (critical for sensitive electronics) with *load support*—but how do they stack up against other common data center flooring systems? This guide breaks down the load-bearing performance of anti-static raised floors vs. alternatives, helping you align your choice with your data center’s current needs and future growth.

Why Load-Bearing Strength Matters More in Data Centers Than Any Other Space

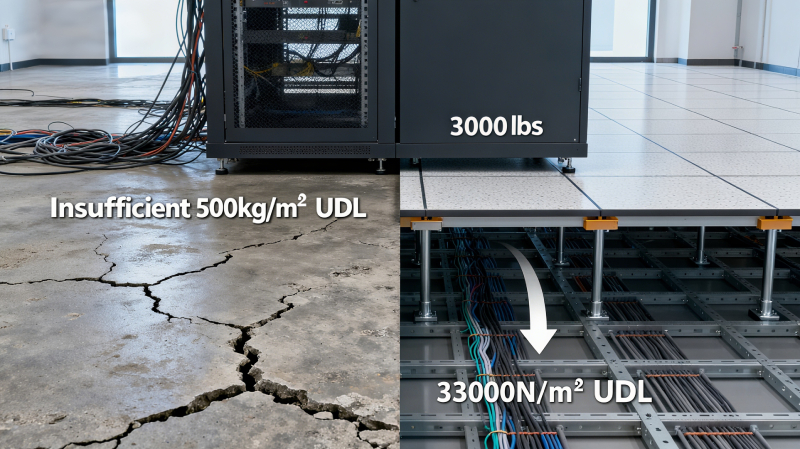

Data centers aren’t like offices or retail stores. A single server cabinet can weigh 2,500–3,000 lbs (1,134–1,361 kg), and a medium-sized data center may house hundreds of these cabinets—plus cooling units, power distribution systems, and maintenance carts that add rolling or impact loads. Even small gaps in load capacity can lead to:

• Permanent floor deformation (compromising cable management under raised floors).

• Equipment tilting or failure (risking data loss or downtime).

• Safety hazards, including floor collapse in extreme cases.

Worse, as data centers scale (e.g., adding high-density AI servers or expanding storage), floor loads only increase. This is why *load-bearing margin*—the gap between a floor’s maximum capacity and your actual equipment weight—is just as important as raw load numbers.

Anti-Static Raised Floor Panels: Load-Bearing Strengths That Fit Data Center Needs

Anti-static raised floors (the most common types for data centers are calcium sulphate and **all-steel**) are engineered specifically for heavy, dynamic data center environments. Their load-bearing capabilities are defined by three key metrics—*concentrated load* (for cabinets), rolling load (for carts), and uniform load (for distributed weight)—and they outperform many alternatives in critical areas.

1. Core Load-Bearing Performance (By Material Type)

Anti-static raised floors aren’t one-size-fits-all—material choice directly impacts load capacity, making them adaptable to different data center needs. (Note: 1 Newton (N) ≈ 0.225 pounds (lbs); 1 Newton per square meter (N/m²) ≈ 0.000209 pounds per square foot (lbs/ft²) for easy unit conversion.)

|

Anti-Static Raised Floor Type

|

Concentrated Load (Typical)

|

Uniform Load (Typical)

|

Rolling Load (10,000 Passes)

|

Best For

|

|

Calcium Sulphate (e.g., CWWIN’s Series)

|

1,960–5,560 N (440–1,250 lbs)

|

9,720–33,000 N/m² (203–690 lbs/ft²)

|

1,566–4,450 N (352–1,000 lbs)

|

High-end data centers, server rooms, and spaces needing both anti-static protection and fire resistance (calcium sulphate is inherently fire-retardant).

|

|

All-Steel (e.g., Anti-Static Floor Panel Series)

|

2,940–8,890 N (661–2,000 lbs)

|

12,500–44,450 N/m² (261–928 lbs/ft²)

|

2,356–6,675 N (529–1,501 lbs)

|

High-density data centers with ultra-heavy equipment (e.g., AI server racks) or frequent maintenance traffic.

|

2. Design Advantages That Boost Practical Load Support

Unlike fixed flooring, anti-static raised floors have structural features that enhance real-world load performance:

• Modular Understructure: Steel pedestals and stringers distribute weight evenly across the subfloor, preventing stress points (a common issue with traditional flooring).

• Edge Sealing: Panels (like CWWIN’s calcium sulphate models) are sealed with PVC trim, which reinforces panel edges and prevents load-induced cracking.

• Compatibility with Heavy Accessories: They easily integrate with cable trays, cooling vents, and weight-distributing pads—critical for supporting uneven loads from equipment like UPS systems.

How Anti-Static Raised Floors Compare to Other Data Center Flooring Systems

To understand their value, let’s compare anti-static raised floors to three other common options: traditional concrete, ceramic tile, and SPC/WPC flooring. We focus on *load capacity*, anti-static performance (a non-negotiable for data centers), and *adaptability*—key factors for purchasing decisions.

1. vs. Traditional Concrete Flooring

Concrete is often seen as “strong,” but it falls short in data center-specific load needs:

• Load Strength: Concrete floors typically support 300–500 kg/m² (61–102 lbs/ft²) of uniform load—*far less* than the 9,720 N/m² (203 lbs/ft²) minimum of calcium sulphate raised floors. For concentrated loads (e.g., server cabinets), concrete may crack without additional reinforcement (e.g., steel beams).

• Anti-Static Performance: Concrete is not inherently anti-static. Adding anti-static coatings is a temporary fix (coatings wear off in 1–2 years), leading to static buildup that damages electronics.

• Adaptability: No underfloor space means cables and cooling systems must be mounted overhead—limiting future expansion and increasing maintenance costs.

Verdict: Concrete fails at both anti-static protection and heavy-equipment load support. It’s only viable for small, low-density data centers (e.g., on-premise server closets).

2. vs. Ceramic Tile Flooring (Non-Raised)

Ceramic tile (e.g., CWWIN’s Ceramic Access Floor Panel Series, but *non-raised versions*) is durable but not designed for data center loads:

• Load Strength: Ceramic tile has a high compressive strength (15,000–20,000 N/m² / 313–419 lbs/ft²) but is brittle—concentrated loads (like cabinet legs) can crack tiles, even with a concrete subfloor. Rolling loads (e.g., maintenance carts) cause further damage over time.

• Anti-Static Performance: Standard ceramic tile is not anti-static. “Anti-static ceramic” requires special glazes, which add cost and still don’t match the permanent static dissipation of raised floor panels.

• Adaptability: No underfloor space means limited cable management—critical for data centers with 100+ cables per rack.

Verdict: Ceramic tile works for low-load areas (e.g., office lobbies adjacent to data centers) but not for equipment rooms.

3. vs. SPC/WPC Flooring

SPC (stone-plastic composite) and WPC (wood-plastic composite) are popular in commercial spaces but are unsuitable for data centers:

• Load Strength: SPC/WPC supports 500–800 N/m² (10.4–16.7 lbs/ft²) of uniform load—*way below* data center requirements. Even light server cabinets will warp or crack these materials.

• Anti-Static Performance: SPC/WPC has no anti-static properties. Static buildup can short-circuit servers, making it a non-starter for equipment areas.

• Adaptability: It’s a floating floor system, which means it can’t support underfloor cooling or heavy accessories.

Verdict: SPC/WPC is only for non-equipment areas (e.g., data center break rooms) and never for server floors.

Key Buying Considerations: Align Load Capacity with Your Data Center’s Needs

When choosing flooring, focus on *practical load requirements*—not, not just maximum numbers. Here’s how to match your choice to your scenario:

1. Assess Your Current and Future Equipment Weight

• Calculate Concentrated Load: Multiply the weight of your heaviest cabinet (e.g., 3,000 lbs) by 1.2 (a 20% safety margin) to get your required concentrated load. For example, a 3,000-lb cabinet needs a floor that supports at least 3,600 lbs of concentrated load (all-steel anti-static floors are ideal here).

• Plan for Expansion: If you’ll add AI servers or storage racks in 2–3 years, choose a floor with extra capacity (e.g., all-steel panels with 8,890 N / 2,000 lbs of concentrated load).

2. Prioritize Anti-Static Compliance

Data centers need floors that meet ANSI/ESD S20.20 (the global anti-static standard). Anti-static raised floors (both calcium sulphate and all-steel) achieve this permanently—unlike coated concrete or ceramic, which degrade over time.

3. Consider Total Cost of Ownership (TCO), Not Just Upfront Price

While anti-static raised floors have a higher initial cost than concrete or SPC, they save money long-term:

• No need for anti-static coating replacements (saves $2–$4 per square foot every 2 years).

• Easier maintenance (access to underfloor cables cuts downtime by 30–50%).

• Better scalability (modular design means you can expand without replacing the entire floor).

Why Anti-Static Raised Floors Are the Top Choice for Modern Data Centers

For data centers prioritizing safety, scalability, and equipment protection, anti-static raised floors outperform all alternatives. They deliver:

• Load strength that handles today’s heavy servers and tomorrow’s expansions.

• Permanent anti-static protection that safeguards sensitive electronics.

• A modular design that reduces maintenance costs and supports future upgrades.

Whether you’re building a new data center or retrofitting an existing space (e.g., converting a warehouse to a server room), anti-static raised floors (like CWWIN’s calcium sulphate or all-steel series) are the only solution that balances load-bearing reliability with data center-specific needs.

Ready to find the right anti-static raised floor for your data center? Contact a flooring expert to get a customized load assessment—no obligation, just data-driven recommendations to keep your equipment safe and your operations running.